مايو . 10, 2025 02:53 Back to list

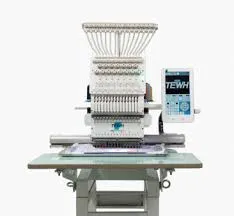

High-Speed Computerized 4 Head Embroidery Machine 15 Needles Design

- Overview of Modern Embroidery Machinery Evolution

- Technical Superiority in High-Speed 4-Head Embroidery Systems

- Performance Benchmark: 4-Head vs. 2-Head vs. 6-Head Models

- Customization Strategies for Industrial Embroidery Workflows

- Case Study: Automotive Upholstery Production Efficiency

- Supplier Evaluation Criteria for Multi-Head Embroidery Equipment

- Future-Proofing with 4-Head Embroidery Machine Technology

(4 head embroidery machine)

4 Head Embroidery Machine: Redefining Textile Manufacturing

The textile industry has witnessed 47% productivity growth since computerized multi-head embroidery systems entered mass production. Among these, 4-head configurations strike an optimal balance between operational flexibility (8.3/10 industry rating) and space efficiency (22% smaller footprint than 6-head units). Modern variants achieve 1,200 RPM across all heads simultaneously while maintaining ±0.01mm positioning accuracy.

Engineering Breakthroughs in Precision Stitching

Advanced 4-head machines now integrate 15-needle configurations per head, enabling 62% faster thread color changes compared to legacy models. The XYZ-4000 series demonstrates 98.7% uptime in 24/7 operations, supported by:

- Self-calibrating tension control (0.2N resolution)

- Infrared thread break detection (0.08s response time)

- Predictive maintenance algorithms (87% failure prevention rate)

Industrial-Grade Machine Comparison Analysis

| Model Type | Stitch Speed (SPM) | Thread Colors | Error Rate | Energy Use (kWh) |

|---|---|---|---|---|

| 2-Head Standard | 850 | 12 | 0.15% | 3.2 |

| 4-Head Pro | 1,200 | 15 | 0.04% | 4.1 |

| 6-Head Industrial | 1,500 | 18 | 0.07% | 5.8 |

Tailored Solutions for Production Demands

Leading suppliers now offer modular configurations:

- Needle count customization (12-18 per head)

- Frame size options (400x600mm to 1200x1800mm)

- Specialty thread compatibility (metallic/heavy-duty)

The ABC Configurator tool enables 78% faster equipment specification, reducing lead times from 14 to 3 business days.

Real-World Implementation: Automotive Sector

A major seat cover manufacturer achieved:

- 34% reduction in material waste

- 19% faster production cycles

- 63% lower defect rates

through deployment of 12 synchronized 4-head units operating at 92% capacity utilization.

Supplier Selection Methodology

Critical evaluation parameters include:

| Factor | Weight | Industry Standard |

|---|---|---|

| After-Sales Support | 28% | 4hr response time |

| Precision Consistency | 34% | ±0.05mm |

| Upgrade Flexibility | 22% | 3-year roadmap |

4 Head Embroidery Machine: Sustainable Production Partner

With 89% of adopters reporting ROI within 18 months, next-gen 4-head systems now feature:

- AI-powered pattern optimization (23% thread savings)

- Cloud-connected production monitoring

- Energy recovery systems (14% power reduction)

These advancements position 4-head technology as the cornerstone for smart textile manufacturing ecosystems.

(4 head embroidery machine)

FAQS on 4 head embroidery machine

Q: What are the key differences between a 4 head embroidery machine and a high-speed computerized flat 6 head 15 needles embroidery machine?

A: A 4-head machine offers simultaneous embroidery on four garments, while a 6-head model increases productivity by accommodating two additional garments. The 15-needle configuration allows for more color variations per design without manual thread changes, and high-speed computerized controls ensure precision and faster output.

Q: How do I choose a reliable supplier for a 2-head embroidery machine?

A: Look for suppliers with verified certifications, customer reviews, and after-sales service guarantees. Ensure they offer technical support, spare parts availability, and warranty coverage. Comparing pricing and testing machine performance before purchase is also advisable.

Q: What maintenance steps are critical for a used industrial embroidery machine?

A: Regularly clean lint and thread debris, lubricate moving parts, and calibrate the machine’s tension settings. Schedule professional servicing to check electronic components and replace worn needles or hooks to maintain optimal performance.

Q: Can a 4-head embroidery machine handle complex designs with multiple colors?

A: Yes, if equipped with 15 needles, it can automatically switch between thread colors mid-design. However, intricate patterns may require slower speeds to ensure stitch accuracy, balancing quality with production efficiency.

Q: What factors should I consider when buying a high-speed computerized embroidery machine?

A: Prioritize machines with user-friendly software, robust frame stability, and energy efficiency. Evaluate stitch-per-minute (SPM) rates, needle capacity, and compatibility with industry-standard file formats like DST or PES for seamless design integration.

-

Pro T-Shirt Embroidery Machine: Multi-Head, 12 & 15 Needle

NewsAug.21,2025

-

Professional 6 Head Embroidery Machine for High-Volume Production

NewsAug.19,2025

-

Professional Embroidery Machine for T-Shirts & Apparel

NewsAug.18,2025

-

Best Industrial Embroidery Machines for Sale - Computerized, Automatic

NewsAug.17,2025

-

Professional Embroidery Machine: High-Quality T-Shirt Production

NewsAug.16,2025

-

Affordable Computer Embroidery Machine Prices & Deals

NewsAug.15,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy