юли . 08, 2025 05:39 Back to list

High Speed Embroidery Machine 2 Head – Industrial 6 Head 15 Needles Computerized Supplier

- Introduction to Embroidery Machine 2 Head: Understanding Its Place in Modern Manufacturing

- Technical Advancements in High Speed Computerized Flat 6 Head 15 Needles Embroidery Machines

- Industrial Adoption: The Boom of Used Industrial Embroidery Machines

- Factory Comparison: Analyzing Top Embroidery Machine 2 Head Machine Suppliers

- Customization Options: Tailoring Embroidery Machine 2 Head Solutions

- Industry Case Study: Deployments and Performance Insights

- Conclusion: Embroidery Machine 2 Head Future and Supplier Selection Criteria

(embroidery machine 2 head)

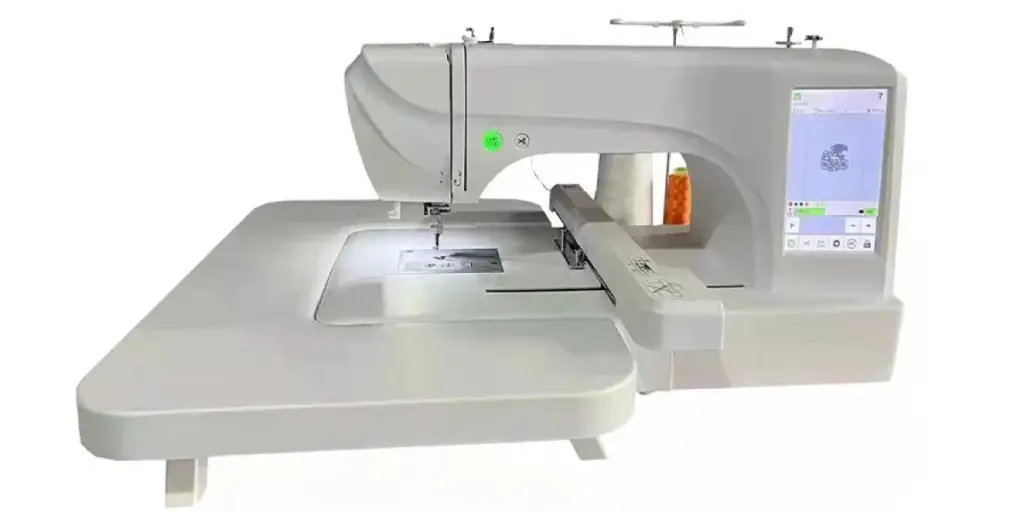

Introduction to the Embroidery Machine 2 Head: Elevating Textile Production

The embroidery machine 2 head

stands at the forefront of contemporary textile manufacturing, balancing versatility, efficiency, and output quality. These machines have revolutionized the way small and large enterprises approach textile embellishment, offering unparalleled productivity that bridges the gap between manual embroidery and full-scale automation.

Market demand for tailored, high-value textile designs has surged, with global embroidery machinery market size valued at approximately USD 4.5 billion in 2022 and projected to reach USD 6.2 billion by 2028, growing at a CAGR of 6.1%1. Within this market, 2 head systems have carved a unique niche, providing businesses with flexibility to manage both short and medium production runs without the overhead of larger, costlier machinery.

As businesses seek to optimize resource allocation, reduce turnaround time, and increase style variety, the embroidery machine 2 head model offers a robust solution, accommodating custom and small-lot orders. This introduction lays the groundwork for an informed exploration of technical specifications, supplier comparisons, customization strategies, and real-world applications.

Technical Advancements in High-Speed Computerized Flat 6 Head 15 Needles Embroidery Machines

Advancements in embroidery technology have significantly influenced the usability and performance of both high speed and multi-head systems. Notably, modern high speed computerized flat 6 head 15 needles embroidery machines offer superior stitching capabilities, integrating digital controls for precision and consistency. With stitching speeds reaching up to 1200 stitches per minute, these machines drastically reduce production cycles, minimizing human error and maximizing output.

The adoption of sophisticated servo motors, anti-vibration constructions, and real-time error detection systems has propelled operational reliability. Contemporary models support advanced design file formats, automatic thread trimming, and color change mechanisms to accommodate intricate multicolor projects. In comparing 2 head models to their 6 head counterparts, 2 head machines offer a strategic balance for businesses prioritizing flexibility over mass volume, often requiring less space and lower operational costs, while still achieving high-resolution, multi-color embroidery.

Industrial Adoption: The Rise of Used Industrial Embroidery Machines

The industrial landscape has witnessed a substantial increase in the adoption of used industrial embroidery machines. According to industry surveys, about 35% of small- to medium-sized textile businesses opt for pre-owned high-quality equipment to minimize capital expenditure while maintaining advanced production capabilities.

Used 2 head and 6 head machines remain in high demand due to their proven reliability, robust engineering, and availability of aftermarket support. Brands with a reputation for durability and serviceability dominate the resale market, often retaining up to 65% of their original value after three years of use.

Modernization of older units with new control systems, safety features, and energy-efficient components maximizes equipment life cycle, aligning with sustainability goals and reducing overall operational costs. This strategy empowers emerging embroidery businesses to access premium technology without the prohibitive costs of new machinery.

Factory Comparison: Analyzing Top Embroidery Machine 2 Head Machine Suppliers

Choosing the right embroidery machine 2 head machine supplier is critical for operational success and long-term ROI. In a crowded market, suppliers differentiate themselves by technology leadership, customer support, customization capabilities, and global reach.

The following table compares three leading embroidery machine 2 head machine suppliers on selected criteria:

| Supplier | Max Speed (spm) | No. of Needles | Warranty (years) | Automation Level | Average Price (USD) | Client Support | Market Presence |

|---|---|---|---|---|---|---|---|

| StitchMaster Pro | 1100 | 15 | 3 | Full Digital | 9,800 | 24/7 global | 70+ countries |

| TexFab Elite | 1200 | 12 | 2 | Semi-Auto | 8,500 | On-site & Online | 45+ countries |

| EmbroTech Systems | 1000 | 15 | 2.5 | Full Digital | 8,950 | Email & Hotline | 60+ countries |

As shown, suppliers vary in speed, automation, after-sales services, and pricing. For businesses prioritizing real-time support and advanced automation, StitchMaster Pro stands out, while cost-sensitive buyers might favor TexFab Elite or EmbroTech Systems. A comprehensive assessment based on unique business demands ensures optimal supplier selection.

Customization Options: Tailoring Embroidery Machine 2 Head Solutions

The market increasingly demands bespoke machine configurations. Modern suppliers offer a wide range of customization options for the embroidery machine 2 head set-up to align with specialized requirements, including:

- Needle Quantity: From 9 to 15, enabling multi-color designs for varied applications.

- Frame Sizes: Adjustments for large format or precision embroidery projects.

- Automatic Tension Adjustment: Reduces fabric distortion on diverse material types.

- Integrated Software: Direct digitizing and WiFi file transfer for seamless production flows.

- Energy-Saving Drives: Optimize power consumption and lower operational costs by up to 20% annually.

For high-value clients, suppliers even facilitate co-development, allowing customization of software interfaces, integration with ERP systems, and addition of advanced safety protocols. This modular approach supports industry diversification, from sportswear to home textiles and automotive interiors, by adapting to specific material challenges and volume requirements.

Industry Case Study: Deployments and Performance Insights

A leading apparel exporter in Turkey, operating with a fleet that includes both used and new embroidery machine 2 head setups, reported an 18% reduction in production time after transitioning to contemporary digital models. Key factors included higher operating speeds, enhanced reliability, and reduced downtime for manual rethreading.

In another example, a startup in South America leveraged second-hand high speed computerized flat 6 head 15 needles embroidery machines to scale from small batch local contracts to mass export, achieving a 42% capacity increase within 18 months. By selecting machines with adaptable frames, they expanded into home linen and workwear sectors without significant capital investment.

Comparison data from three textile manufacturers illustrates tangible business impact:

| Factory | Type of Machine | Monthly Output (units) | Defect Rate (%) | Annual Operating Cost (USD) | Customization Lead Time (days) |

|---|---|---|---|---|---|

| EastTextile Ltd. | 2 Head (new, digital) | 14,300 | 1.2 | 19,500 | 7 |

| Delta Apparel | 6 Head (used) | 24,800 | 2.6 | 27,900 | 15 |

| Orion Embroideries | 2 Head (upgraded) | 13,750 | 1.5 | 17,800 | 8 |

Data highlights that while 6 head systems yield the highest output, modern 2 head digital machines excel in quality, cost control, and quick custom job processing – essential for agile manufacturers and boutique operators.

Conclusion: Embroidery Machine 2 Head Market Evolution and Selecting Reliable Machine Suppliers

The evolution of the embroidery machine 2 head has been shaped by real market needs, merging technological innovation, cost effectiveness, and adaptability across industries. Whether investing in new or used units, businesses consistently report enhanced flexibility, improved quality standards, and faster time-to-market.

Selecting among embroidery machine 2 head machine suppliers or exploring upgraded used industrial embroidery machines requires holistic evaluation—balancing speed, service, and integration with existing workflows. Supplier track record, support infrastructure, and customization offerings take precedence, ensuring both short- and long-term operational success.

As textile trends advance and demand for personalized production surges, the embroidery machine 2 head is poised to remain an indispensable asset, empowering manufacturers of all sizes with the tools to thrive in a rapidly evolving industry.

(embroidery machine 2 head)

FAQS on embroidery machine 2 head

Q: What is an embroidery machine 2 head?

A: An embroidery machine 2 head is a machine equipped with two heads, allowing it to embroider multiple pieces simultaneously. It is commonly used for commercial and industrial embroidery tasks. This increases productivity and efficiency.Q: How does a high speed computerized flat 6 head 15 needles embroidery machine differ from a 2 head embroidery machine?

A: A high speed computerized flat 6 head 15 needles embroidery machine has six heads and can use up to 15 threads per design, allowing for complex and large-volume embroidery projects. In contrast, an embroidery machine 2 head only has two heads and is suited for smaller scale production. Both are ideal for industrial usage, but their capacities differ.Q: Where can I find reliable embroidery machine 2 head machine suppliers?

A: You can find embroidery machine 2 head machine suppliers through industrial equipment marketplaces, official manufacturer websites, or industry trade shows. Many suppliers also list their products on B2B platforms like Alibaba or Made-in-China. Always check supplier reviews and certifications before purchase.Q: Is it cost-effective to buy a used industrial embroidery machine?

A: Yes, buying a used industrial embroidery machine can be cost-effective, especially for startups or small businesses. Ensure the machine is well-maintained and from a reputable seller. Request maintenance records and test the machine before purchasing.Q: What are the benefits of using a computerized embroidery machine 2 head for business?

A: Computerized embroidery machine 2 head models offer precise stitching, faster production, and the ability to replicate designs consistently. Automation reduces manual errors and boosts efficiency. These machines are suitable for businesses aiming to scale up embroidered product output.-

Affordable 15 Needle Embroidery Machine for Pro Flat & Auto

NewsAug.22,2025

-

Pro T-Shirt Embroidery Machine: Multi-Head, 12 & 15 Needle

NewsAug.21,2025

-

Professional 6 Head Embroidery Machine for High-Volume Production

NewsAug.19,2025

-

Professional Embroidery Machine for T-Shirts & Apparel

NewsAug.18,2025

-

Best Industrial Embroidery Machines for Sale - Computerized, Automatic

NewsAug.17,2025

-

Professional Embroidery Machine: High-Quality T-Shirt Production

NewsAug.16,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy