dec . 28, 2024 19:12 Back to list

12 needle embroidery machine factories

Exploring the World of 12% Needle Embroidery Machine Factories

The embroidery industry has seen significant advancements in technology, leading to the development of high-efficiency machines that cater to the growing demand for customized and intricate designs. Among these innovations, the 12% needle embroidery machine stands out as a critical tool for manufacturers, enabling them to enhance productivity and improve the quality of their embroidered products. In this article, we will delve into the realm of 12% needle embroidery machine factories, exploring their significance, operational dynamics, and the impact they have on the embroidery market.

What Are 12% Needle Embroidery Machines?

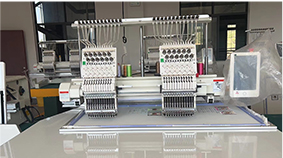

12% needle embroidery machines are specialized devices that utilize a set number of needles—12 in this case—allowing for simultaneous stitching of multiple colors and designs. This capability significantly reduces the time required to complete embroidery tasks compared to traditional single-needle machines. With the versatility to handle various fabrics, including cotton, polyester, and denim, these machines are ideally suited for both small-scale artisans and large-scale production facilities.

The Production Capacity of Factories

Factories specializing in 12% needle embroidery machines are designed to maximize efficiency and meet the diverse needs of the market. They employ advanced manufacturing techniques and automation to streamline processes from assembly to quality control. Many of these factories integrate computer-aided design (CAD) software that allows designers to create intricate patterns and layouts before production begins. This digital approach not only reduces errors but also accelerates the time from concept to completion.

Furthermore, the output of these factories is often substantial, catering to both domestic and international markets. For instance, a well-established factory can produce hundreds of machines per month, equipped with the latest technology to ensure they meet the high standards expected by customers. This production capacity allows businesses to respond swiftly to market demands, whether it be for personalized promotional items or large-scale apparel manufacturing.

The Role of Skilled Labor

12 needle embroidery machine factories

While automation plays a vital role in the operation of 12% needle embroidery machine factories, skilled labor remains an indispensable asset. Technicians and operators with expertise in embroidery machine operation are essential for ensuring that machines function optimally and that the finished products meet quality standards. Comprehensive training programs within factories equip employees with the knowledge to troubleshoot common issues and perform routine maintenance, thereby extending the lifespan of the machinery.

Moreover, designers with a keen eye for aesthetics and technical proficiency are integral to the creative process. They collaborate with clients to bring their visions to life, transforming ideas into tangible embroidered products that reflect the desired branding or artistic intent.

Economic Impact and Sustainability Challenges

The establishment of 12% needle embroidery machine factories contributes significantly to the local economy by creating employment opportunities and fostering entrepreneurship. Many small businesses rely on these machines for their operations, particularly in regions where traditional crafts are prevalent. The accessibility of advanced embroidery technology has allowed these businesses to compete in a global market, thus bolstering local economies.

However, the embroidery industry also faces sustainability challenges. The production processes involved in creating embroidery machines and the eventual output can lead to environmental concerns, particularly regarding waste and energy consumption. As such, many factories are now exploring eco-friendly practices, such as using sustainable materials and incorporating energy-efficient technologies, to mitigate their environmental footprint.

Conclusion

In summary, 12% needle embroidery machines represent a significant leap in the embroidery industry, revolutionizing the way designs are executed and enhancing productivity across various sectors. Factories dedicated to their production play a crucial role in meeting the demands of a dynamic market, supported by skilled labor and innovative technologies. While the economic benefits are evident, addressing sustainability challenges remains an important consideration as the industry continues to evolve. As we look to the future, the synergy between technology, craftsmanship, and eco-conscious practices will undoubtedly shape the next chapter of the embroidery landscape.

-

Professional Embroidery Machines: Precision for T-Shirts & More

NewsAug.26,2025

-

6 Head Embroidery Machine for Professional & Commercial Production

NewsAug.25,2025

-

Computerized T-Shirt Embroidery Machine | Fast, Flat, & Affordable

NewsAug.24,2025

-

Cheap Commercial Embroidery Machine for Sale | Automatic 12-Needle

NewsAug.23,2025

-

Affordable 15 Needle Embroidery Machine for Pro Flat & Auto

NewsAug.22,2025

-

Pro T-Shirt Embroidery Machine: Multi-Head, 12 & 15 Needle

NewsAug.21,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy