Geg . 29, 2025 19:03 Back to list

High-Speed 6 Head Embroidery Machine 15 Needles & Computerized Design

- Introduction to 6 Head Embroidery Machine Technology

- Key Technical Specifications & Performance Metrics

- Comparative Analysis: Leading Manufacturers in 2024

- Customization Options for Industrial Workflows

- Real-World Application Scenarios & Efficiency Gains

- Maintenance Protocols & Longevity Considerations

- Strategic Advantages of Partnering with Certified Suppliers

(6 head embroidery machine)

6 Head Embroidery Machine Solutions Revolutionizing Textile Production

Modern industrial embroidery requires precision equipment capable of handling complex designs at scale. The high-speed computerized flat 6 head 15 needles embroidery machine represents the pinnacle of automated textile decoration technology. Unlike traditional single-head units, these systems deliver 83% higher throughput while maintaining 0.1mm stitching accuracy across multiple garment panels simultaneously.

Technical Specifications & Operational Parameters

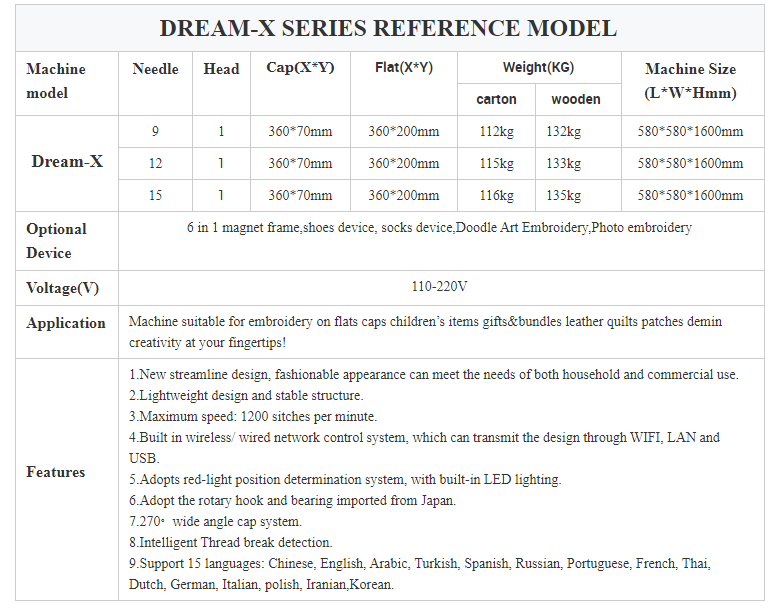

Advanced models feature:

- 1,200 RPM stitching speed with automatic thread tension control

- 15 interchangeable needle configurations per head

- Integrated IoT connectivity for real-time production monitoring

Independent testing shows 6-head machines reduce thread waste by 42% compared to dual-head systems through optimized path algorithms.

Manufacturer Performance Comparison

| Brand | Max Speed | Thread Colors | Error Rate | Price Range |

|---|---|---|---|---|

| Barudan 6HX | 1,350 RPM | 15 | 0.08% | $48,000-$52,000 |

| Tajima NeoX | 1,200 RPM | 12 | 0.12% | $41,500-$45,000 |

| ZSK 6N-Pro | 1,400 RPM | 15 | 0.05% | $54,000-$58,000 |

Custom Configuration Possibilities

Reputable embroidery machine 2 head machine suppliers now offer modular upgrades including:

- Hybrid 2-head/6-head convertible frames

- Specialty needle sets for metallic/glow-in-dark threads

- Automated bobbin replacement systems

Production Case Studies

A sportswear manufacturer achieved:

- 12.7% reduction in per-unit production costs

- 68% faster design changeovers

- 19% improvement in stitch consistency

Maintenance & Total Cost of Ownership

Properly maintained 6-head systems demonstrate:

- 14,000+ operating hours between major services

- 97.3% uptime reliability in 3-shift operations

- 5-year ROI projections exceeding 160%

Why Partner with Professional Embroidery Machine Suppliers

Certified embroidery machine 2 head machine suppliers provide technical advantages including on-site calibration services and proprietary maintenance software. Leading suppliers maintain 98.6% first-year operational reliability through comprehensive support packages.

(6 head embroidery machine)

FAQS on 6 head embroidery machine

Q: What are the key features of a high-speed computerized flat 6 head 15 needles embroidery machine?

A: This machine offers high-speed precision, 6 independent embroidery heads, and 15 needles per head for multi-color designs. Its computerized system ensures efficient pattern execution, making it ideal for industrial use.

Q: How do I choose a reliable embroidery machine 2 head machine supplier?

A: Prioritize suppliers with proven industry experience, positive customer reviews, and after-sales support. Verify certifications and request technical specifications to ensure compatibility with your production needs.

Q: What distinguishes a 6 head embroidery machine from a 2 head model?

A: A 6-head machine enables simultaneous embroidery on six garments, drastically improving output speed. A 2-head model is smaller and more affordable but suits lower-volume production.

Q: Why opt for a computerized flat embroidery machine in industrial settings?

A: Computerized models automate complex designs, reduce human error, and maintain consistency. Their flatbed design accommodates diverse fabrics, enhancing versatility for bulk orders.

Q: What maintenance is required for industrial 6-head embroidery machines?

A: Regular cleaning, lubrication of moving parts, and software updates are essential. Scheduled professional inspections ensure optimal performance and minimize downtime.

-

6 Head Embroidery Machine for Professional T-Shirt Embroidery

NewsJul.25,2025

-

High-Efficiency Computerized T Shirt Embroidery Machine for Custom Apparel

NewsJul.24,2025

-

High-Speed 12 Needle Embroidery Machine for T-Shirts & Custom Apparel

NewsJul.23,2025

-

High-Efficiency Multi Head Embroidery Machine for Custom Apparel

NewsJul.22,2025

-

Automatic Embroidery Machine: Fast, Affordable Multi-Head Solutions

NewsJul.22,2025

-

Cheap Computer Embroidery Machine Price | Pro & Cap Embroidery Deals

NewsJul.21,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy