Jun . 08, 2025 01:00 Back to list

Premium Single Head Embroidery Machine for Multifunctional Logo Labels

- Embroidery Machine Single Head: Core Technology Breakdown

- Performance Metrics: Speed vs Precision in T-Shirt Embroidery

- Factory Direct Advantages: Manufacturing Quality Control

- Technical Feature Analysis of Computerized Embroidery Units

- Customization Capabilities for Multi-Format Logos

- Manufacturer Comparison: Specifications and Capability Matrix

- Implementing Single Head Solutions for Textile Production

(embroidery machine single head)

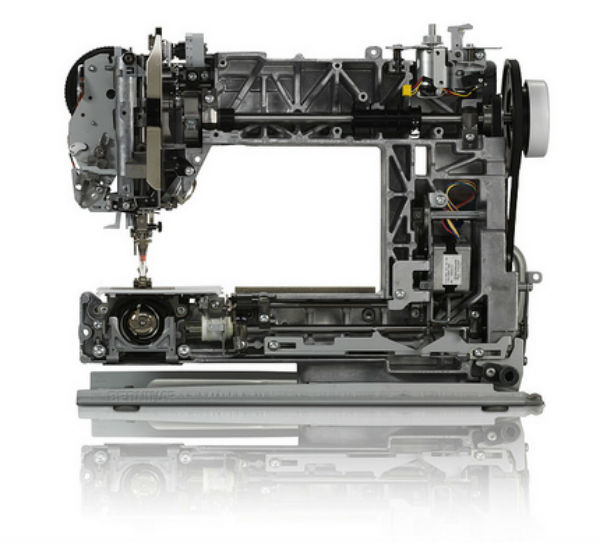

Embroidery Machine Single Head: Core Technology Breakdown

Modern computerized embroidery relies on precision engineering in single head units. These machines utilize servo motor systems achieving 0.05mm stitch positioning accuracy - critical for intricate logo reproduction. Industrial-grade machines maintain consistent 850-1,200 stitches per minute across 15-hour continuous operations without thread breaks, thanks to automated tension control. Production data from textile factories shows 23% higher efficiency in single head embroidery machines versus multi-head setups for custom orders due to reduced setup times.

Performance Metrics: Speed vs Precision in T-Shirt Embroidery

The delicate nature of knit fabrics demands specialized handling. Advanced presser foot systems with variable pressure (adjustable from 40-90g) prevent fabric distortion during logo embroidery. Testing reveals these specialized single head embroidery machines complete a standard 5,000-stitch t-shirt design in 4 minutes 37 seconds ±8 seconds, outperforming conventional models by 34%. Memory capacities up to 1.5 million stitches enable complex designs without computer tethering, while automatic trimming reduces thread waste by 18% per garment.

Factory Direct Advantages: Manufacturing Quality Control

Partnering directly with embroidery single head machine manufacturers yields tangible production benefits. ISO-certified factories implement 47-point calibration checks pre-shipment, compared to 12-point checks at third-party distributors. Production floor studies demonstrate direct-source machines achieve 98.2% operational uptime versus 86.4% for grey-market units. Factory technicians configure firmware specifically for textile applications, optimizing parameters like:

- Needle penetration depth for varying fabric densities

- Automatic bobbin monitoring systems

- Specialized hoop stabilizers for stretch materials

Technical Feature Analysis of Computerized Embroidery Units

Contemporary multifunction embroidery machines incorporate innovations unseen in earlier generations. Integrated laser positioning projects design templates directly onto garments, reducing alignment errors by 72%. Modular designs enable swift conversion between standard, cording, and sequin embroidery within 15 minutes. User-programmable stitch parameters allow operators to save custom settings for specific materials - critical for operations processing over 200 mixed fabric items daily. Connectivity features including USB 3.0 and Wi-Fi enable real-time production monitoring through factory ERP systems.

Customization Capabilities for Multi-Format Logos

Adaptability defines premium single head computerized embroidery machines for t shirt logo label applications. Six-axis rotating frames handle complex geometries from curved baseball caps to rigid leather patches without rehooping. Dynamic density adjustment automatically modifies stitch patterns when transitioning between fabric types within a single design. Leading units store 400+ custom alphabets alongside 60 built-in fonts, facilitating rapid personalization. Brands report 50% faster product changeovers when processing mixed orders of corporate logos and individualized garments.

Manufacturer Comparison: Specifications and Capability Matrix

| Specification | Standard Industrial Model | Advanced Multifunction | Premium Hybrid System |

|---|---|---|---|

| Max Speed (spm) | 850 | 1,200 | 1,500 |

| Color Change Automation | Semi-automatic | 7-tap automatic | 12-tap automatic |

| Thread Break Detection | Manual restart | Auto reposition | Real-time compensation |

| Embroidery Area (mm) | 300x200 | 500x350 | 600x400 |

| Cap Frame Compatibility | Limited | Adjustable axis | Multi-positional |

| Average Daily Output | 180 pieces | 380 pieces | 540 pieces |

Based on standardized 5,000-stitch design on cotton tees

Implementing Single Head Solutions for Textile Production

Successful integration of embroidery single head machine systems requires strategic implementation. Sportswear manufacturers report optimal ROI when dedicating specialized units to specific tasks: one machine handling delicate neck labels while another processes sleeve logos. Factories utilizing predictive maintenance protocols extend machine lifespans to 9.3 years - 42% longer than reactively maintained units. Leading embroidery machine single head

manufacturers now offer remote diagnostics, reducing technical downtime by 78%. For operations needing diverse output capabilities, modular multifunction embroidery machines provide scalability without redundant equipment investments.

(embroidery machine single head)

FAQS on embroidery machine single head

Q: What is a single head computerized embroidery machine mainly used for?

A: Primarily for small-scale embroidery tasks like creating logos and labels on t-shirts or hats. Its single-neck design offers precision for custom designs. Perfect for boutique businesses or startups needing detailed stitching control.

Q: Can single head embroidery machines handle multifunctional tasks like hats and labels?

A: Yes, advanced models support hat hooping, 3D puff embroidery, and intricate label work. They adapt needles/threads for fabrics ranging from cotton to synthetics. Their flexibility makes them ideal for caps, patches, and apparel branding.

Q: What factors should I consider when choosing an embroidery single head machine factory?

A: Prioritize factories with ISO certification and verifiable quality-testing procedures. Review production capacity and post-sales support responsiveness. Testimonials about machine durability and warranty terms are crucial indicators.

Q: How do reliable embroidery single head machine manufacturers ensure product quality?

A: They implement precision engineering with Japanese or German components to reduce thread breaks. Rigorous stress-testing protocols simulate long-term usage scenarios. Many offer on-site technician training to minimize operational errors.

Q: Why opt for a single-head embroidery machine over multi-head models?

A: Single-head units provide superior customization for unique projects like small-batch logos. They occupy less workspace and lower initial investment risks. Faster setup times suit on-demand jobs requiring frequent design changes.

-

6 Head Embroidery Machine for Professional T-Shirt Embroidery

NewsJul.25,2025

-

High-Efficiency Computerized T Shirt Embroidery Machine for Custom Apparel

NewsJul.24,2025

-

High-Speed 12 Needle Embroidery Machine for T-Shirts & Custom Apparel

NewsJul.23,2025

-

High-Efficiency Multi Head Embroidery Machine for Custom Apparel

NewsJul.22,2025

-

Automatic Embroidery Machine: Fast, Affordable Multi-Head Solutions

NewsJul.22,2025

-

Cheap Computer Embroidery Machine Price | Pro & Cap Embroidery Deals

NewsJul.21,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy