Oct . 31, 2024 04:02 Back to list

12 head embroidery machine price factories

Exploring the Costs and Options of 12-Head Embroidery Machines

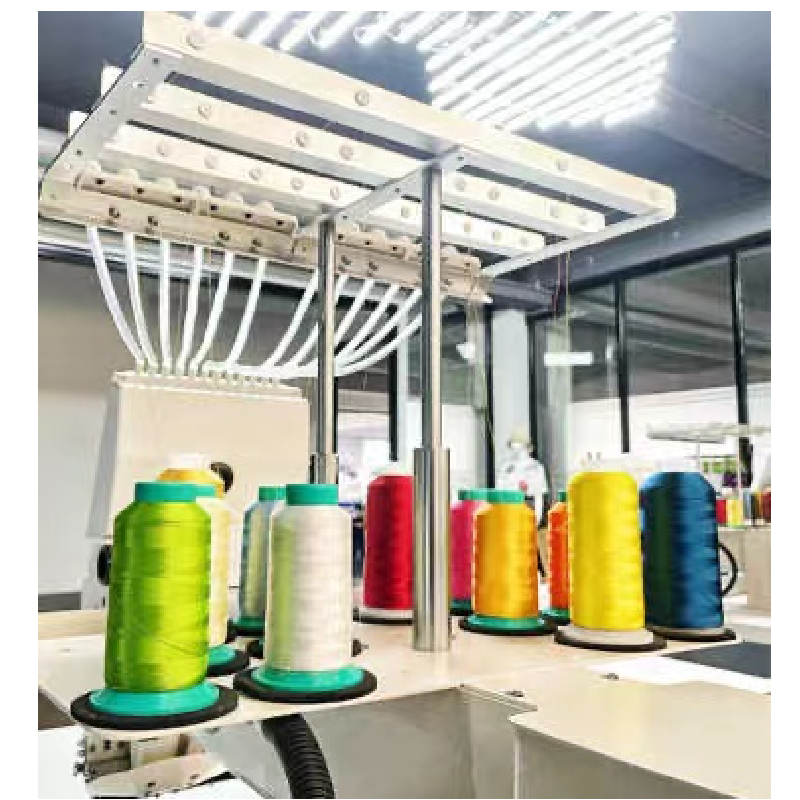

In the world of textile and apparel manufacturing, embroidery plays a crucial role in enhancing the aesthetic appeal of products. The demand for high-quality embroidery has led to significant advancements in embroidery technology, particularly with multi-head machines. Among these, the 12-head embroidery machine stands out as a popular choice for businesses looking to balance productivity and efficiency. However, understanding the price points and factors influencing these costs is essential for any prospective buyer.

A 12-head embroidery machine is designed to facilitate large-scale embroidery operations. By enabling simultaneous stitching on multiple items, these machines dramatically increase productivity compared to single-head or even smaller multi-head machines. Businesses that rely on custom embroidery services, such as promotional merchandise, uniforms, or personalized gifts, can significantly benefit from the capabilities offered by a 12-head machine. But before making a purchase, it’s crucial to understand the price ranges and what influences these costs.

Prices for 12-head embroidery machines can vary widely based on several factors. On average, you can expect to pay anywhere from $20,000 to $70,000 or more. This price range is influenced by the brand, machine specifications, and additional features. For instance, well-established brands known for their reliability and advanced technology may command higher prices. Features such as automated color changes, built-in digitizing software, and higher stitch speeds can also contribute to overall costs.

12 head embroidery machine price factories

Additionally, the geographical location of the manufacturer or factory can impact pricing. Machines produced in countries with lower manufacturing costs might be significantly cheaper, but it’s essential to consider the trade-offs in quality and support. Buyers should also factor in potential shipping costs and import duties when sourcing machines from international suppliers.

Investing in a 12-head embroidery machine is not solely about the initial purchase price. Prospective buyers should also consider ongoing operational costs, such as maintenance, software updates, and consumables (like threads and stabilizers). Regular maintenance is crucial for ensuring a machine’s longevity and performance, and neglecting this can lead to costly repairs down the line.

Furthermore, businesses should assess their specific needs and production goals to determine if a 12-head machine is the right fit. Factors such as the volume of orders, types of garments or items to be embroidered, and the complexity of designs can influence whether a 12-head machine is necessary or if a smaller machine would suffice.

In conclusion, while the upfront cost of a 12-head embroidery machine may be significant, the potential for increased productivity and efficiency in embroidery operations often justifies the investment. By understanding the various factors that influence price and carefully evaluating business needs, companies can make informed decisions that enhance their production capabilities and drive growth in the competitive embroidery market. As demand for high-quality embroidered products continues to rise, investing in the right machinery will undoubtedly play a pivotal role in a business’s success.

-

Affordable 15-Needle Embroidery Machine with GPT-4 Turbo

NewsAug.02,2025

-

Affordable Commercial Embroidery Machines for Sale

NewsAug.01,2025

-

Top AI Embroidery Machine Manufacturers | GPT-4 Turbo Tech

NewsJul.31,2025

-

Affordable Computer Embroidery Machines | Best Prices

NewsJul.31,2025

-

Cheap T Shirt Printing Embroidery Machine with Multi Needle Efficiency

NewsJul.30,2025

-

High-Quality T Shirt Embroidery Machine – Multi & 12/15 Needle Options

NewsJul.30,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy