Jan . 22, 2025 05:29 Back to list

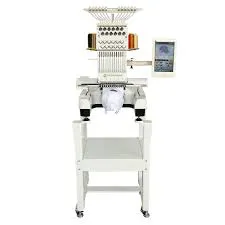

High speed Multi head embroidery machine t-shirt flat hat computer embroidery machine for sale

Choosing the right embroidery machine can significantly affect the quality and efficiency of your embroidery projects. Multi-head embroidery machines present a notable advantage for businesses and large-scale embroidery operations. These machines offer multiple embroidery heads working simultaneously, which can drastically increase production speed and ensure consistency in design replication across various items.

In terms of expertise, knowing the machine's capability for speed is indispensable. Production speed can vary significantly; typically, an efficient machine will operate at around 1,000 stitches per minute. Speed control options should also be present to customize for delicate fabrics or intricate designs without compromising stitch quality. The type of stitch selection available is another critical consideration. Look for models that support a broad spectrum of stitches, offering versatility across projects. Machines that automatically trim threads and offer thread tension control are invaluable for maintaining the integrity of each item embroidered. Enhancing the user experience with training support is another crucial element. Premier manufacturers often provide comprehensive manuals, video tutorials, and even on-site training sessions. Such resources reduce the learning curve, enabling operators to utilize the machine to its full potential swiftly. Brand reputation can influence decision-makers considerably. Industry-leaders like Brother and Melco have repeatedly shown excellence in innovation and customer satisfaction. These brands not only produce machines with exceptional functionality but also offer excellent customer service and after-sales support, which enhances trustworthiness and long-term value. Finally, the overall cost of operations, including maintenance and energy efficiency, should not be overlooked. While initial costs are significant, long-term energy savings and reduced downtime due to minimal maintenance needs can present substantial financial benefits. In summation, the best multi-head embroidery machine is a balanced blend of innovative technology, robust build quality, diverse functionality, and reliable support services. Whether an entry-level enterprise or a seasoned embroidery business, making an informed decision based on detailed criteria will elevate the production capacity and quality outputs, securing a competitive edge in the creative embroidery marketplace.

In terms of expertise, knowing the machine's capability for speed is indispensable. Production speed can vary significantly; typically, an efficient machine will operate at around 1,000 stitches per minute. Speed control options should also be present to customize for delicate fabrics or intricate designs without compromising stitch quality. The type of stitch selection available is another critical consideration. Look for models that support a broad spectrum of stitches, offering versatility across projects. Machines that automatically trim threads and offer thread tension control are invaluable for maintaining the integrity of each item embroidered. Enhancing the user experience with training support is another crucial element. Premier manufacturers often provide comprehensive manuals, video tutorials, and even on-site training sessions. Such resources reduce the learning curve, enabling operators to utilize the machine to its full potential swiftly. Brand reputation can influence decision-makers considerably. Industry-leaders like Brother and Melco have repeatedly shown excellence in innovation and customer satisfaction. These brands not only produce machines with exceptional functionality but also offer excellent customer service and after-sales support, which enhances trustworthiness and long-term value. Finally, the overall cost of operations, including maintenance and energy efficiency, should not be overlooked. While initial costs are significant, long-term energy savings and reduced downtime due to minimal maintenance needs can present substantial financial benefits. In summation, the best multi-head embroidery machine is a balanced blend of innovative technology, robust build quality, diverse functionality, and reliable support services. Whether an entry-level enterprise or a seasoned embroidery business, making an informed decision based on detailed criteria will elevate the production capacity and quality outputs, securing a competitive edge in the creative embroidery marketplace.

Latest news

-

Best Industrial Embroidery Machines For Sale | AI Tech

NewsAug.03,2025

-

Affordable 15-Needle Embroidery Machine with GPT-4 Turbo

NewsAug.02,2025

-

Affordable Commercial Embroidery Machines for Sale

NewsAug.01,2025

-

Top AI Embroidery Machine Manufacturers | GPT-4 Turbo Tech

NewsJul.31,2025

-

Affordable Computer Embroidery Machines | Best Prices

NewsJul.31,2025

-

Cheap T Shirt Printing Embroidery Machine with Multi Needle Efficiency

NewsJul.30,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy