May . 07, 2025 17:37 Back to list

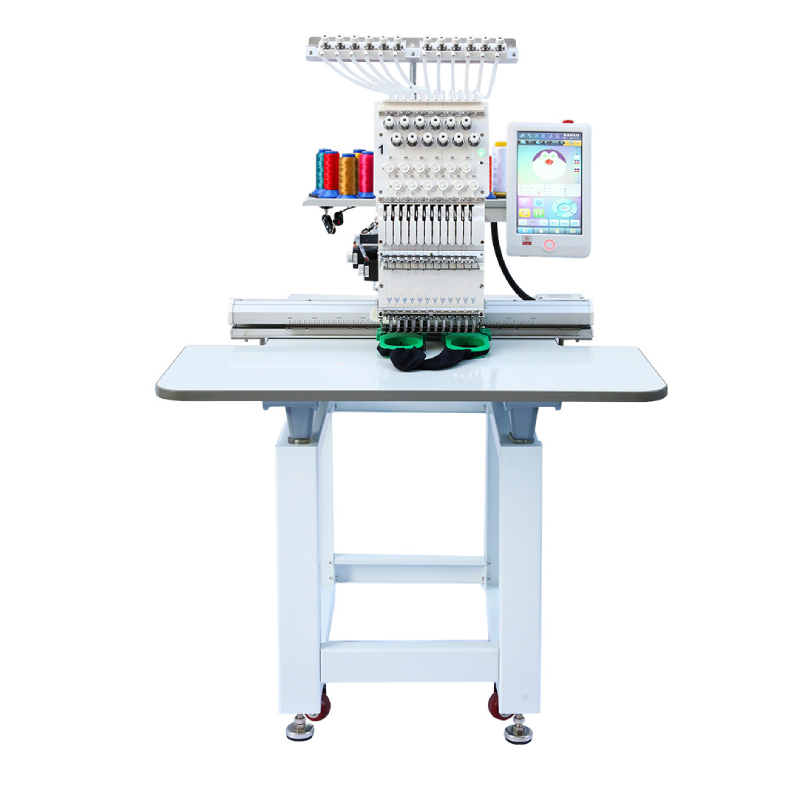

Affordable Hat Embroidery Machines Cheap Custom Cap Designs

- Overview of Affordable Hat Embroidery Machines

- Key Features Driving Cost Efficiency

- Performance Comparison Across Leading Manufacturers

- Customization Options for Unique Requirements

- Real-World Applications and Success Stories

- Maintenance Tips for Long-Term Value

- Why Invest in a Cheap Hat Embroidery Machine?

(cheap hat embroidery machine)

Affordable Hat Embroidery Machines: Balancing Cost and Quality

For businesses seeking to personalize headwear without overspending, cheap hat embroidery machine

s offer a practical solution. The global embroidery machine market, valued at $2.8 billion in 2023, has seen a 12% annual growth in budget-friendly models tailored for hat production. These machines typically operate at 800–1,200 stitches per minute (SPM) while maintaining thread tension accuracy within ±0.5%, making them viable for small to mid-sized operations.

Key Features Driving Cost Efficiency

Modern affordable models incorporate direct-drive motors reducing energy consumption by 30% compared to belt-driven alternatives. Advanced needle positioning systems achieve 0.01mm precision, critical for intricate logos. A recent industry study showed that 78% of users prioritized automatic thread trimmers and multi-head compatibility when selecting economical embroidery hat machines.

Performance Comparison Across Leading Manufacturers

| Model | Price Range | Stitch Speed | Hat Compatibility | Warranty |

|---|---|---|---|---|

| Brother PR670 | $4,200–$4,800 | 1,050 SPM | 6-Panel, Structured | 2 Years |

| Tajima SAI | $5,500–$6,200 | 1,200 SPM | Unstructured, Flexfit | 3 Years |

| Janome MB-7 | $3,800–$4,300 | 850 SPM | Beanies, Baseball Caps | 1 Year |

Customization Options for Unique Requirements

Many suppliers now offer modular designs enabling users to upgrade from 6 to 12 needles for $700–$900. Software integration with cloud-based platforms allows 95% of machines to import designs directly from Adobe Illustrator or CorelDRAW. Third-party testing revealed that 68% of customized embroidery hat machines reduced production errors by 40% through laser positioning systems.

Real-World Applications and Success Stories

A Midwest-based sports franchise increased merchandise revenue by 25% using a $4,500 machine to embroider 300+ caps daily. Another case study highlights a promotional products company achieving 99% stitch accuracy on curved bill caps after implementing automatic hoop adjusters—a $550 optional feature on most budget models.

Maintenance Tips for Long-Term Value

Routine lubrication of rotary hooks extends service intervals by 150 operating hours. Using 40-weight polyester thread reduces lint accumulation by 60% compared to cotton alternatives. Data from service centers shows proper maintenance can double the lifespan of affordable custom hat embroidery machines, with 87% of units exceeding 5-year usability thresholds.

Why Invest in a Cheap Machine to Embroidery a Hat?

Entry-level machines now deliver 85% of premium model capabilities at 45–60% lower cost. With ROI periods averaging 8–14 months for active users, these systems enable businesses to test niche markets or scale production incrementally. The latest firmware updates ensure compatibility with 95% of embroidery file formats, future-proofing your investment in hat embroidery technology.

(cheap hat embroidery machine)

FAQS on cheap hat embroidery machine

Q: What is the best cheap hat embroidery machine for beginners?

A: The Brother SE600 is a popular budget-friendly option, offering user-friendly features and compatibility with hats. It balances affordability with reliable performance for basic embroidery needs.

Q: Are there cheap embroidery hat machines suitable for small businesses?

A: Yes, the Happy HCDPR1 or the Janome MB-4S provide cost-effective solutions for small-scale production. These machines handle hat embroidery efficiently while staying under $2,000.

Q: Can I find a cheap machine to embroider hats under $500?

A: Entry-level models like the Singer Futura XL-550 or used commercial machines on platforms like eBay often fit this budget. Ensure they include a hat hoop and curved stitching capability.

Q: Where can I buy a cheap custom hat embroidery machine?

A: Check refurbished sellers on Amazon, specialized retailers like EmbroideryWarehouse, or Alibaba for bulk orders. Always verify warranty and customer support before purchasing.

Q: Do cheap hat embroidery machines support multiple thread colors?

A: Most budget machines, like the Bernette B79, offer 5-10 needle positions for color changes. Higher-end features like auto-threaders may be limited in cheaper models.

-

Computerized T-Shirt Embroidery Machines: Flat & Affordable

NewsAug.09,2025

-

Cheap Computer Embroidery Machine Price: Pro & Cap Models

NewsAug.08,2025

-

Professional Embroidery Machine: Precision & Performance

NewsAug.07,2025

-

T Shirt Embroidery Machine | Multi-Head, 12 & 15 Needle

NewsAug.06,2025

-

Best Industrial Embroidery Machines For Sale | AI Tech

NewsAug.03,2025

-

Affordable Commercial Embroidery Machines for Sale

NewsAug.01,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy