Oct . 12, 2024 08:48 Back to list

Exploring the Rise of Computerized Embroidery Production Facilities in the Modern Era

The World of Computer Embroidery Factories

In recent years, the textile industry has witnessed a remarkable transformation, significantly influenced by advancements in technology. One of the most notable innovations is computer embroidery. This process has revolutionized how embroidery is produced in factories, ushering in an era where precision, speed, and creativity coexist seamlessly.

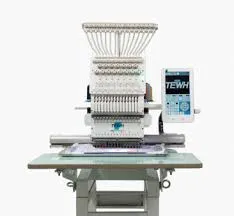

Computer embroidery factories utilize state-of-the-art machines equipped with computer-aided design (CAD) software to create intricate designs. Unlike traditional hand embroidery, which can be time-consuming and labor-intensive, computer embroidery allows for the rapid production of complex patterns with uniformity and consistency. As a result, manufacturers can significantly increase output while maintaining high quality. This has made computer embroidery especially appealing to businesses looking to meet the growing demand for customized and personalized products.

One of the primary advantages of computer embroidery is its versatility. Factories can create a wide range of products, from corporate uniforms and promotional items to intricate garments and home textiles. The ability to customize designs easily is particularly beneficial for small businesses and startups. They can offer unique products that stand out in a competitive market, thereby attracting a broader customer base. For larger brands, computer embroidery provides the opportunity to maintain brand identity through consistent logo reproduction on uniforms and merchandise.

computer embroidery factories

Moreover, the integration of technology in embroidery has also paved the way for innovation in design. Designers can create detailed patterns digitally, allowing for experimentation with colors, textures, and styles without the need for physical prototypes. This capability not only accelerates the design process but also fosters creativity, inspiring new trends in fashion and home decor.

Environmental sustainability is another significant aspect of modern computer embroidery factories. Traditional embroidery often involves excess fabric waste and energy consumption. In contrast, many computer embroidery operations prioritize sustainable practices by optimizing fabric usage and employing energy-efficient machinery. Furthermore, advancements in digitized patterns enable factories to cut precise designs, minimizing waste. As consumers become more environmentally conscious, businesses with sustainable practices are more likely to gain customer loyalty.

However, the rise of technology in the embroidery industry also brings challenges. Factory owners must ensure that their staff is adequately trained to operate complex equipment and software. Investing in staff training programs is crucial to maximizing the capabilities of these machines and maintaining high standards of quality. Additionally, as technology evolves, businesses must stay updated with the latest advancements to remain competitive, requiring ongoing investment and adaptation.

In conclusion, computer embroidery factories have transformed the embroidery landscape, offering unparalleled advantages in terms of efficiency, creativity, and sustainability. By harnessing the power of technology, these factories can produce high-quality products that cater to the diverse needs of consumers today. As the industry continues to evolve, the balance between traditional craftsmanship and modern innovation will be key in shaping the future of computer embroidery. With a commitment to quality and sustainability, these factories are well-positioned to thrive in the fast-paced world of fashion and textile design, showcasing the beauty and versatility of embroidery in modern consumer culture.

-

Affordable Commercial Embroidery Machines for Sale

NewsAug.01,2025

-

Top AI Embroidery Machine Manufacturers | GPT-4 Turbo Tech

NewsJul.31,2025

-

Affordable Computer Embroidery Machines | Best Prices

NewsJul.31,2025

-

Cheap T Shirt Printing Embroidery Machine with Multi Needle Efficiency

NewsJul.30,2025

-

High-Quality T Shirt Embroidery Machine – Multi & 12/15 Needle Options

NewsJul.30,2025

-

High-Efficiency Computerized T Shirt Embroidery Machine for Custom Apparel

NewsJul.29,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy