Dec . 05, 2024 16:47 Back to list

Modern Automated Embroidery Factories Revolutionizing Textile Production and Design Efficiency

The Rise of Computerized Embroidery Factories

In the modern textile industry, the evolution of technology has revolutionized the way designs are created and produced. One of the most significant advancements in this sector is the introduction of computerized embroidery factories. These facilities have transformed traditional embroidery methods, allowing for increased efficiency, enhanced creativity, and greater accuracy in the production of embroidered goods.

Computerized embroidery machines combine the artistry of traditional craftsmanship with the precision of modern technology. These machines are capable of creating intricate and complex designs that were once time-consuming and labor-intensive to produce manually. With the ability to store thousands of designs and patterns, computerized embroidery eliminates the need for repetitive manual work and enables factories to deliver customized products quickly and at scale.

One of the main advantages of computerized embroidery is speed. Where traditional methods may require hours, or even days, to complete a design by hand, computerized machines can replicate the same patterns in a fraction of the time. This rapid production capability meets the demands of a fast-paced market, where customer expectations for quick turnarounds are rising. Businesses can manage larger orders more efficiently, allowing them to maintain a competitive edge.

Additionally, the precision provided by computerized embroidery machines is unmatched. These machines operate using digitized designs that are translated into stitch patterns, ensuring that every piece is identical and free from human error. This consistency is particularly crucial for brands seeking to maintain their reputation for quality. From simple logos to complex artwork, the results are consistently high, which is essential for product branding and market appeal.

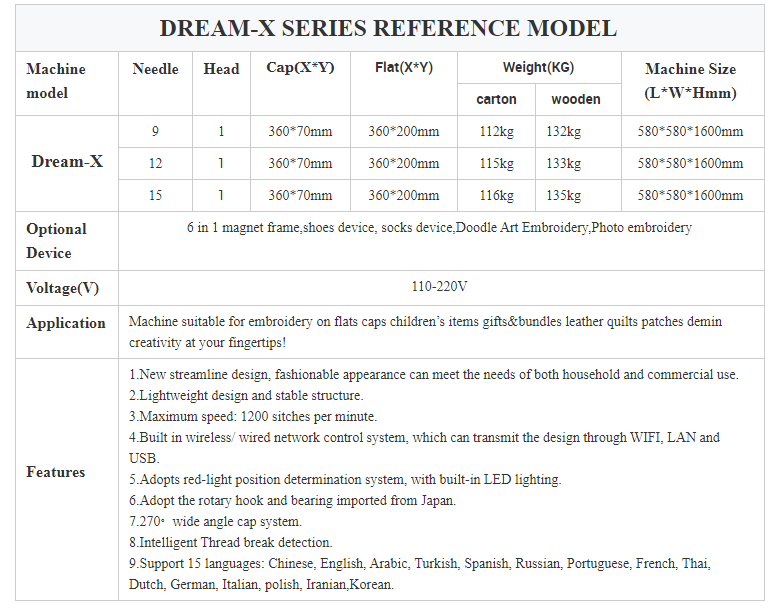

computerized embroidery factories

Moreover, computerized embroidery factories have opened up new avenues for customization. Customers can easily request personalized designs, whether for corporate uniforms, promotional items, or individual gifts. The digital nature of the designs allows for quick adaptations, enabling factories to cater to unique customer requests without extensive lead times. This customization capability enhances customer satisfaction and fosters loyalty in an increasingly competitive landscape.

The integration of computerized embroidery technology also supports sustainable practices in the textile industry. By optimizing material usage and minimizing waste, these factories can produce embroidered items more responsibly. Digital design processes allow for precise calculations on material requirements, reducing excess fabric and thread. Additionally, the ability to produce on demand means that factories can avoid overproduction, which is a significant contributor to waste in the fashion industry.

However, the rise of computerized embroidery factories does not come without challenges. The initial investment in advanced machinery and software can be substantial, putting pressure on smaller businesses. Furthermore, while technology can streamline operations, it also requires a skilled workforce capable of managing, maintaining, and operating these sophisticated machines. Therefore, training and education are essential to ensure that employees can effectively leverage technology for optimal production outcomes.

Despite these challenges, the benefits of computerized embroidery factories are evident. They create opportunities for innovation and growth within the sector. As businesses continue to adapt to consumer demands and global market trends, investing in technology will be critical for success. The ability to combine traditional artistry with modern efficiency positions these factories well for the future of the textile industry.

In conclusion, computerized embroidery factories represent a significant leap forward in the embroidery sector, marrying artistry with cutting-edge technology. Their ability to produce high-quality, customized designs quickly and efficiently has transformed the textile landscape. As sustainability and speed become ever more critical in today’s market, these factories are poised to play a crucial role in shaping the future of embroidery. The journey from traditional methods to computerized solutions signifies not just a change in technique, but an advancement that enhances the possibilities for creativity and efficiency in textile production. Moving forward, it will be fascinating to observe how these advancements continue to influence the industry and empower both manufacturers and consumers alike.

-

Affordable Commercial Embroidery Machines for Sale

NewsAug.01,2025

-

Top AI Embroidery Machine Manufacturers | GPT-4 Turbo Tech

NewsJul.31,2025

-

Affordable Computer Embroidery Machines | Best Prices

NewsJul.31,2025

-

Cheap T Shirt Printing Embroidery Machine with Multi Needle Efficiency

NewsJul.30,2025

-

High-Quality T Shirt Embroidery Machine – Multi & 12/15 Needle Options

NewsJul.30,2025

-

High-Efficiency Computerized T Shirt Embroidery Machine for Custom Apparel

NewsJul.29,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy