Nov . 04, 2024 13:12 Back to list

Innovative Technology in Computerized Embroidery Machines for Creative Textile Design

The Evolution and Impact of Computerized Embroidery Machines

In recent years, the world of textile decoration has undergone a significant transformation, primarily due to the advent of computerized embroidery machines. These sophisticated devices have revolutionized not only the way embroidery is performed but also the scale at which it can be produced. With advanced technology at their core, computerized embroidery machines are making waves across the fashion, home décor, and promotional products industries.

Understanding Computerized Embroidery Machines

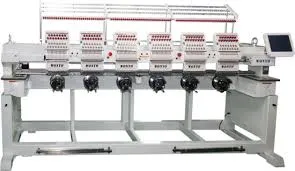

At their essence, computerized embroidery machines are automated devices that allow for precise stitching of intricate designs on fabrics. Unlike traditional embroidery, which relies heavily on manual skills and labor, computerized machines utilize specialized software to create designs and patterns that can be replicated with remarkable accuracy. They are equipped with various features such as multiple needles, automated thread cutting, and intuitive interfaces, making them ideal for both small and large production runs.

One of the most significant advancements in these machines is the incorporation of digital design tools. Users can create or modify patterns through embroidery software, giving them the flexibility to customize designs as needed. This capability is invaluable for businesses looking to personalize products for clients or for artists wanting to experiment with unique concepts.

Benefits of Computerized Embroidery Machines

The benefits of using computerized embroidery machines extend beyond mere convenience; they also enhance production efficiency and consistency. For businesses, these machines allow for rapid turnaround times, enabling firms to meet customer demands swiftly. The ability to store hundreds of designs in the internal memory streamlines the production process, as operators can switch between projects without the hassle of manually reconfiguring the machine for each new design.

Quality is another crucial aspect that computerized embroidery machines address. The precision of automated stitching minimizes errors, ensuring that each piece produced adheres to the highest standards. This level of quality is essential, particularly for businesses in competitive markets where branding and presentation are paramount. Customizable options also enable companies to maintain brand consistency by producing high-quality embroidered logos and designs across different products.

computerized embroidery machine

Moreover, these machines empower smaller businesses and independent artisans to enter the market. The affordability of entry-level computerized embroidery machines has lowered the barrier for aspiring entrepreneurs to start their own embroidery businesses. This democratization of technology encourages creativity, allowing individuals to explore new designs and offerings without requiring a large investment in labor.

Challenges and Considerations

While the conveniences of computerized embroidery machines are evident, they are not without challenges. Initial investment costs can be substantial, particularly for high-end models, which may deter some businesses from making the transition. Furthermore, operators must possess a certain level of technical proficiency to maximize the machines' potential, which may necessitate additional training.

Maintenance is also critical; these machines require regular care to ensure their longevity and performance. Users must be prepared to invest time and resources into upkeep, as neglecting maintenance may lead to malfunctions or diminished production quality.

The Future of Computerized Embroidery

Looking ahead, the future of computerized embroidery machines appears promising. As technology continues to evolve, we are likely to witness further advancements in machine capabilities, including enhanced software features and connectivity options. For instance, integration with artificial intelligence and machine learning may allow for smarter design generation, potentially suggesting designs based on trends or previous user preferences.

In addition, the rise of sustainable practices within the fashion and textiles industry may also influence how computerized embroidery machines are utilized. Innovations such as eco-friendly materials and energy-efficient machines are likely to become more prevalent, allowing for responsible production methods.

In conclusion, computerized embroidery machines mark a significant step forward in the textile industry, combining traditional artistry with modern technology. Their ability to enhance precision, efficiency, and creativity will undoubtedly continue to shape the landscape of embroidery for years to come, illustrating the profound impact of technology on traditional crafts. As we embrace this evolution, the potential for innovative designs and sustainable practices remains bright, paving the way for a new era in textile production.

-

Best Industrial Embroidery Machines For Sale | AI Tech

NewsAug.03,2025

-

Affordable 15-Needle Embroidery Machine with GPT-4 Turbo

NewsAug.02,2025

-

Affordable Commercial Embroidery Machines for Sale

NewsAug.01,2025

-

Top AI Embroidery Machine Manufacturers | GPT-4 Turbo Tech

NewsJul.31,2025

-

Affordable Computer Embroidery Machines | Best Prices

NewsJul.31,2025

-

Cheap T Shirt Printing Embroidery Machine with Multi Needle Efficiency

NewsJul.30,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy