Sep . 19, 2024 19:20 Back to list

embroidery industrial machine factories

The Rise of Embroidery Industrial Machine Factories

Embroidery has long been an art form, connecting communities through intricate designs and personal expression. With the advent of technology, the landscape of embroidery has transformed dramatically, particularly with the establishment of industrial machine factories specializing in embroidery production. This shift not only caters to the growing demand for embroidered goods but also significantly enhances efficiency and creativity in the textile industry.

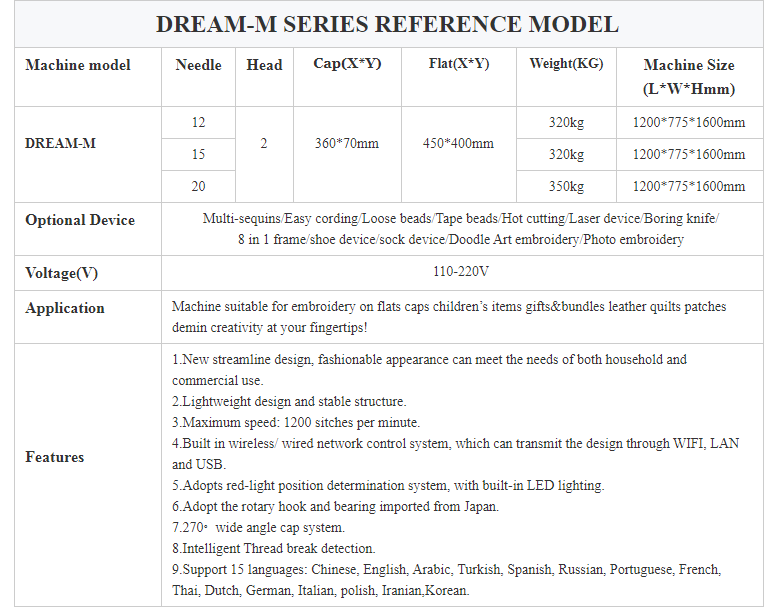

Industrial embroidery machines are revolutionizing how designs are created and replicated. These sophisticated machines can operate at high speeds while maintaining precision, meaning that businesses can scale their production without compromising quality. The factories equipped with these machines are usually highly automated, allowing for a reduction in labor costs and an increase in output. This efficiency is vital in today’s fast-paced market, where trends can shift overnight.

One of the key advantages of industrial embroidery machine factories is their capability to produce intricate designs that were once only achievable by hand. With computerized embroidery machines, designers can create complex patterns that are automatically stitched onto fabrics. This technology not only reduces the time required to produce items but also opens the door to innovative artistic possibilities. Businesses can offer a greater variety of products without the burden of extensive manual labor.

embroidery industrial machine factories

Moreover, these factories play a crucial role in meeting the demand for custom embroidery. As personalization continues to gain traction among consumers, companies are increasingly looking for ways to incorporate bespoke elements into their products. Industrial embroidery machine factories can efficiently handle small batch orders and customized designs, giving businesses the flexibility to cater to individual customer preferences without incurring significant costs.

Sustainability is another critical aspect of modern embroidery machine factories. The use of advanced machinery allows for more efficient material usage, reducing waste in the production process. Additionally, many factories are now adopting eco-friendly practices, such as using water-soluble threads and formulations that minimize environmental impact. This commitment to sustainability resonates with consumers who are becoming more conscious of the ecological effects of their purchases.

Geographically, many embroidery machine factories are concentrated in regions known for textile production. Areas in Asia, for example, have developed strong manufacturing hubs, often benefitting from lower labor costs and access to raw materials. However, there is a growing trend of reshoring, with some companies establishing factories closer to their markets to reduce shipping times and improve supply chain resilience. This shift indicates a strategic pivot in how businesses are approaching production in the face of globalization.

In conclusion, embroidery industrial machine factories are transforming the embroidery landscape. These facilities not only enhance production efficiency but also push the boundaries of design and sustainability in the textile industry. As consumer demands evolve, these factories are poised to play an even greater role in shaping the future of embroidery, marrying tradition with technology to create products that resonate with modern aesthetics and values. The journey of embroidery from handcraft to industrialization marks a significant milestone, heralding a new era of creativity and innovation in textile manufacturing.

-

Best Industrial Embroidery Machines For Sale | AI Tech

NewsAug.03,2025

-

Affordable 15-Needle Embroidery Machine with GPT-4 Turbo

NewsAug.02,2025

-

Affordable Commercial Embroidery Machines for Sale

NewsAug.01,2025

-

Top AI Embroidery Machine Manufacturers | GPT-4 Turbo Tech

NewsJul.31,2025

-

Affordable Computer Embroidery Machines | Best Prices

NewsJul.31,2025

-

Cheap T Shirt Printing Embroidery Machine with Multi Needle Efficiency

NewsJul.30,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy