Feb . 10, 2025 10:49 Back to list

embroidery machine 12 head price supplier

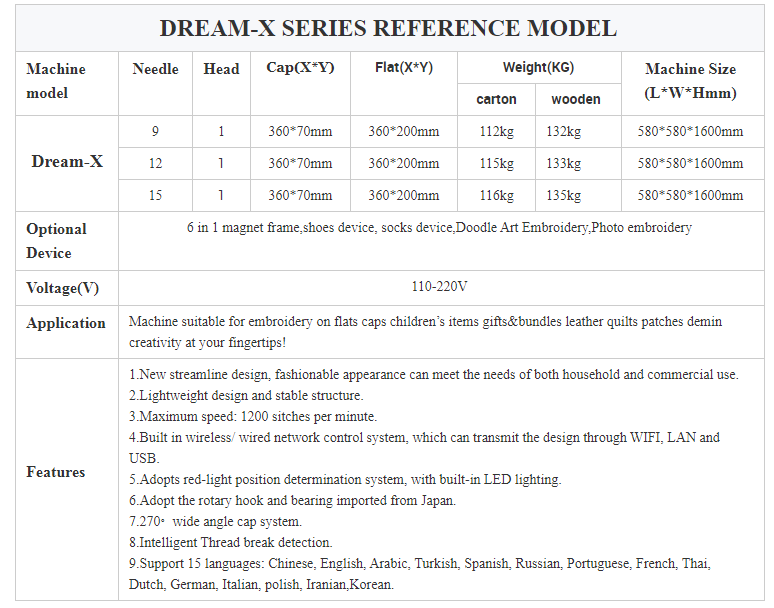

Navigating the market for embroidery machines can be daunting, especially when considering a 12-head embroidery machine. Known for their precision and efficiency, these machines are a significant investment, crucial for scaling up production in any embroidery business. For those who seek to optimize this investment, understanding the intricate details regarding pricing, suppliers, and operational benefits becomes essential.

Beyond just the initial purchase price, it's crucial to consider the cost of ownership over time. This encompasses routine maintenance costs, the availability of replacement parts, and the machine's energy efficiency. Suppliers with a proven track record often have partnerships with manufacturers, ensuring a steady supply of parts and support which can be a significant advantage. Industry reviews and user testimonials offer practical insights into the performance of specific models and suppliers. Engaging in forums or consulting industry experts can provide transparency about potential challenges, such as the learning curve associated with advanced machine features or the real-world support experiences provided by suppliers. For those venturing into the world of embroidery production, investing in a 12-head embroidery machine is a step towards scaling operations efficiently. By choosing a supplier with demonstrated expertise and excellent service offerings, businesses can not only ensure they receive a high-quality machine but also secure ongoing support that contributes to operational success. Ultimately, when selecting an embroidery machine supplier, prioritizing expertise, transparency, and trust is vital. A supplier focused on building long-term partnerships will deliver not just a machine, but a comprehensive solution tailored to elevate your embroidery business. Engaging with seasoned professionals and leveraging their experience can illuminate the path to making an informed decision, ensuring that your business stays competitive and innovative in a demanding market.

Beyond just the initial purchase price, it's crucial to consider the cost of ownership over time. This encompasses routine maintenance costs, the availability of replacement parts, and the machine's energy efficiency. Suppliers with a proven track record often have partnerships with manufacturers, ensuring a steady supply of parts and support which can be a significant advantage. Industry reviews and user testimonials offer practical insights into the performance of specific models and suppliers. Engaging in forums or consulting industry experts can provide transparency about potential challenges, such as the learning curve associated with advanced machine features or the real-world support experiences provided by suppliers. For those venturing into the world of embroidery production, investing in a 12-head embroidery machine is a step towards scaling operations efficiently. By choosing a supplier with demonstrated expertise and excellent service offerings, businesses can not only ensure they receive a high-quality machine but also secure ongoing support that contributes to operational success. Ultimately, when selecting an embroidery machine supplier, prioritizing expertise, transparency, and trust is vital. A supplier focused on building long-term partnerships will deliver not just a machine, but a comprehensive solution tailored to elevate your embroidery business. Engaging with seasoned professionals and leveraging their experience can illuminate the path to making an informed decision, ensuring that your business stays competitive and innovative in a demanding market.

Latest news

-

Best Industrial Embroidery Machines For Sale | AI Tech

NewsAug.03,2025

-

Affordable 15-Needle Embroidery Machine with GPT-4 Turbo

NewsAug.02,2025

-

Affordable Commercial Embroidery Machines for Sale

NewsAug.01,2025

-

Top AI Embroidery Machine Manufacturers | GPT-4 Turbo Tech

NewsJul.31,2025

-

Affordable Computer Embroidery Machines | Best Prices

NewsJul.31,2025

-

Cheap T Shirt Printing Embroidery Machine with Multi Needle Efficiency

NewsJul.30,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy