Dec . 17, 2024 06:02 Back to list

embroidery machine caps factory

The World of Embroidery Machine Caps Factories

In the realm of textile manufacturing, embroidery has established itself as a celebrated art form. Among its various applications, cap embroidery stands out, transforming basic headwear into customizable fashion statements. The embroidery machine caps factory plays a crucial role in this process, providing the technology and craftsmanship needed to bring designs to life. This article delves into the inner workings, benefits, and future of cap embroidery factories, emphasizing their significance in today’s fashion and promotional industries.

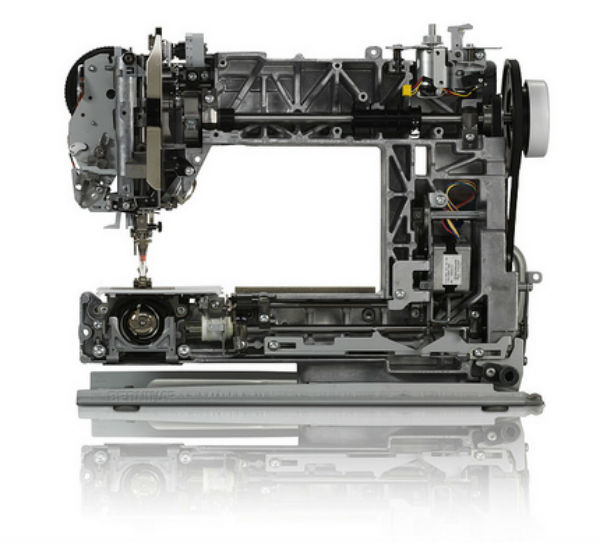

Understanding Embroidery Machine Technology

At the heart of any embroidery caps factory lies sophisticated technology. Modern embroidery machines are marvels of engineering, designed to handle intricate designs while maintaining speed and precision. These machines use advanced software that allows designers to create patterns digitally. Once a design is finalized, it is digitized—converted into a language the machine can understand—and then embroidered onto caps using various threads.

The selection of the right embroidery machine is crucial for a factory. While some machines are capable of executing standard designs, others can handle 3D puff embroidery, which adds depth and texture to the finished product. Factories tend to invest in multi-needle and multi-head machines, which allow them to produce numerous caps simultaneously, enhancing productivity and meeting the demands of large orders.

Cap Customization A Growing Trend

The popularity of customized caps has soared in recent years. From fashion brands to corporate entities, everyone seeks unique caps that resonate with their branding. This demand has led to a surge in cap embroidery factories that offer tailored services. Companies can order caps featuring their logos, slogans, or custom graphics, suitable for promotional events or fashion lines.

Besides commercial use, individuals also turn to these factories for personalized items. Whether it’s for family reunions, sports teams, or personal gifts, customized embroidered caps have become a popular choice. Factories typically provide an array of cap styles—such as baseball caps, snapbacks, and beanies—so customers can choose products that best match their aesthetic or functional needs.

The Manufacturing Process

The manufacturing process in embroidery machine caps factories can be broken down into several stages. Initially, raw materials such as blank caps and threads are sourced. Quality control at this stage is crucial, as the quality of the materials directly affects the final product.

embroidery machine caps factory

Once materials are ready, the design is transferred to the machine. Embroidery software plays a significant role here; it not only dictates the stitch type and density but also ensures that colors are accurately represented in the final product. After the machine is set up, the actual embroidery process begins. High-speed machines can embroider multiple caps simultaneously, significantly cutting down production time.

After embroidery, caps go through a quality check. This ensures that there are no flaws in the stitching or discrepancies in design. Once approved, the caps are cleaned, pressed, and packaged for delivery.

Environmental Considerations

In an era where sustainability is paramount, embroidery machine caps factories are also exploring eco-friendly options. The textile industry, often criticized for its environmental impact, is gradually shifting towards more sustainable practices. This includes using organic or recycled materials for both caps and threads, employing energy-efficient machinery, and minimizing waste during the production process.

The Future of Embroidery Machine Caps Factories

Looking ahead, the future of embroidery machine caps factories appears promising. With the rise of e-commerce, more consumers are seeking personalized products online, creating a steady demand for custom embroidery. Factories that can adapt to quickly changing trends, provide high-quality products, and maintain sustainable practices are likely to thrive.

Moreover, technology continues to advance, with the integration of artificial intelligence and data analytics shaping manufacturing processes. Smart embroidery machines that can adjust settings on-the-fly based on real-time feedback could revolutionize the production line, enhancing efficiency and reducing errors.

Conclusion

Embroidery machine caps factories are at the intersection of art and technology, delivering bespoke products that cater to a wide array of customers. As they continue to evolve and embrace sustainability, these factories will play a pivotal role in shaping the future of fashion and promotional branding. With their commitment to quality and customization, they not only enhance consumer choice but also contribute to the rich tapestry of modern apparel manufacturing.

-

Affordable 15-Needle Embroidery Machine with GPT-4 Turbo

NewsAug.02,2025

-

Affordable Commercial Embroidery Machines for Sale

NewsAug.01,2025

-

Top AI Embroidery Machine Manufacturers | GPT-4 Turbo Tech

NewsJul.31,2025

-

Affordable Computer Embroidery Machines | Best Prices

NewsJul.31,2025

-

Cheap T Shirt Printing Embroidery Machine with Multi Needle Efficiency

NewsJul.30,2025

-

High-Quality T Shirt Embroidery Machine – Multi & 12/15 Needle Options

NewsJul.30,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy