Sep . 22, 2024 06:52 Back to list

embroidery machine multi head factories

The Rise of Multi-Head Embroidery Machine Factories

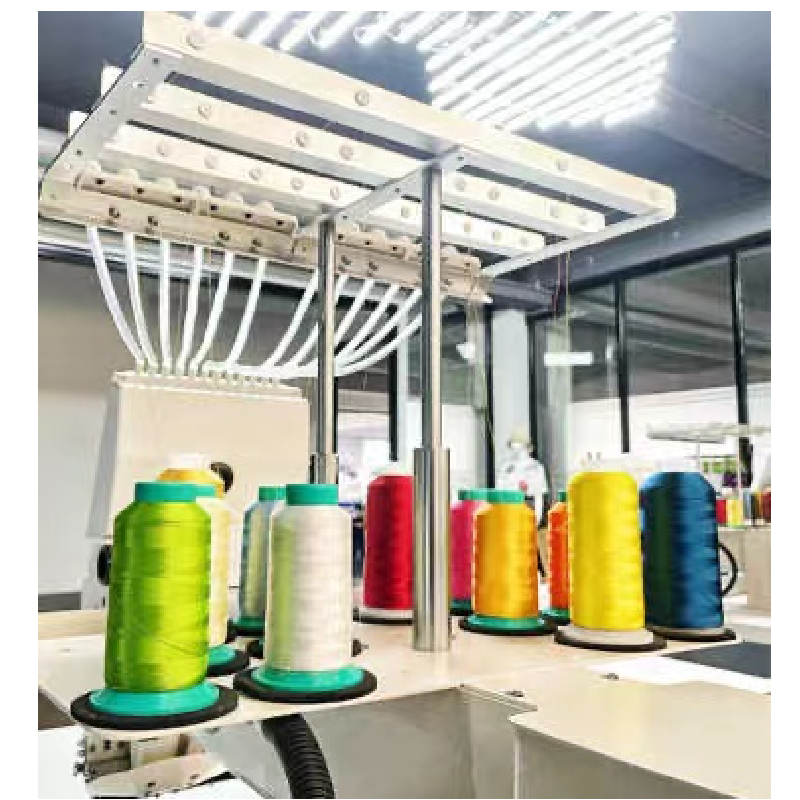

In the ever-evolving world of textile manufacturing, multi-head embroidery machines have emerged as a game-changer, transforming the production landscape for businesses ranging from small startups to large-scale operations. Dedicated factories specializing in these innovative machines are popping up globally, responding to the burgeoning demand for high-quality, customizable embroidered products.

Multi-head embroidery machines, which feature several needle heads working simultaneously, allow manufacturers to produce intricate designs with incredible efficiency. Compared to single-head machines, they significantly increase production speed and reduce labor costs. This efficiency is particularly valuable in today’s fast-paced market, where quick turnaround times are essential for customer satisfaction and competitiveness.

The Rise of Multi-Head Embroidery Machine Factories

Additionally, advancements in technology have made modern multi-head embroidery machines more user-friendly and versatile. Many come equipped with sophisticated software that allows for complex digitizing, enabling designers to create intricate patterns and logos with precision. This technological leap has empowered businesses to expand their product offerings, catering to niche markets that seek unique, customized designs.

embroidery machine multi head factories

The establishment of specialized factories for these machines has also led to increased collaboration within the industry. As embroidery businesses invest in state-of-the-art equipment, they often share best practices and innovative techniques with one another. This collaborative spirit fosters a culture of continuous improvement, ensuring that factories remain competitive and responsive to market demands.

Moreover, the rise of e-commerce has further fueled the demand for personalized products, creating fantastic opportunities for multi-head embroidery machine factories. Consumers are increasingly seeking one-of-a-kind items that reflect their individuality, whether it’s monogrammed clothing or custom patches for bags. As a result, factories that can adapt to this demand by offering customization options and quick turnaround times are thriving.

Sustainability is also becoming a crucial factor in the operations of multi-head embroidery machine factories. Many manufacturers are now focusing on eco-friendly practices, utilizing sustainable materials and energy-efficient machinery. This shift not only responds to consumer preferences but also aligns with global efforts to reduce waste in the textile industry.

In conclusion, multi-head embroidery machine factories are at the forefront of a revolution in textile manufacturing. Their ability to produce high-quality, customized designs quickly and efficiently positions them as vital players in today’s market. As technology continues to advance and consumer preferences shift towards personalization and sustainability, these factories are poised for continued growth and innovation, shaping the future of the embroidery industry. The increasing demand for personalized products and the collaborative spirit among manufacturers will only accelerate this trend, ensuring that multi-head embroidery machines remain an integral part of the fabric of modern manufacturing.

-

Affordable 15-Needle Embroidery Machine with GPT-4 Turbo

NewsAug.02,2025

-

Affordable Commercial Embroidery Machines for Sale

NewsAug.01,2025

-

Top AI Embroidery Machine Manufacturers | GPT-4 Turbo Tech

NewsJul.31,2025

-

Affordable Computer Embroidery Machines | Best Prices

NewsJul.31,2025

-

Cheap T Shirt Printing Embroidery Machine with Multi Needle Efficiency

NewsJul.30,2025

-

High-Quality T Shirt Embroidery Machine – Multi & 12/15 Needle Options

NewsJul.30,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy