Feb . 06, 2025 06:17 Back to list

Good quality factory use Multi heads 15 needles embroidery machines industrial computerized

The world of embroidery has entered a new era with advanced machinery that has transformed traditional needlework into a streamlined and efficient process. As a business owner looking for embroidery machines for sale directly from factories, understanding the available options can empower your enterprise to produce high-quality embroidered products with ease. This exploration delves into the intricate details that make a significant difference.

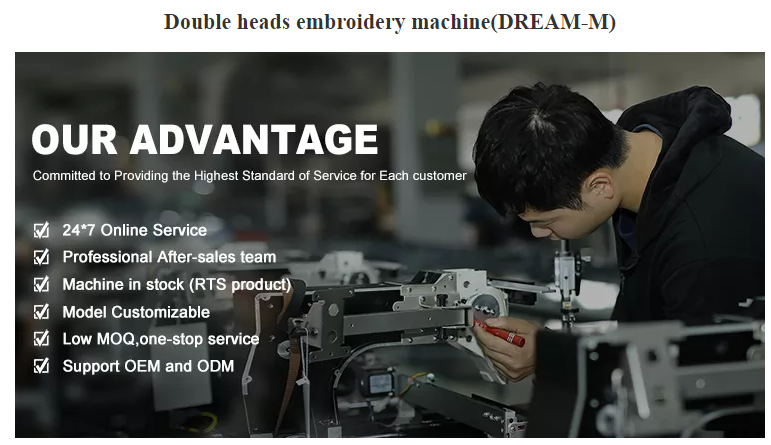

Energy Efficiency and Environmental Considerations Modern factories are increasingly focused on producing energy-efficient embroidery machines. Low energy consumption not only reduces operational costs but also aligns with global sustainability goals. Features such as energy-saving modes and eco-friendly materials are becoming standard in high-quality machines. This consideration is essential for businesses committed to reducing their carbon footprint, appealing to environmentally-conscious consumers. After-Sales Support and Training Comprehensive after-sales support elevates the buying experience significantly. Factories that provide extensive training sessions and 24/7 customer support ensure that businesses can swiftly address any operational challenges. Access to a knowledgeable support team facilitates smoother integration of new machines into existing operations, maximizing return on investment. Authoritative Resources and Networks Establishing connections with factories producing embroidery machines opens doors to authoritative networks. Leveraging insights and updates from industry leaders, forums, and exhibitions nurtures a deep understanding of the latest trends and innovations. Businesses can refine their production lines by incorporating cutting-edge techniques, thus remaining competitive and relevant in a rapidly evolving market. In conclusion, selecting embroidery machines from reputable factories involves a thorough evaluation of quality control, technological integration, customizability, durability, energy efficiency, support systems, and industry connections. Prioritizing these elements not only optimizes operational efficiency but also reassures stakeholders of the enterprise's dedication to exemplary crafting standards. As the market for embroidery goods continues to expand, investing in high-caliber machinery will invariably pave the way for sustained business success.

Energy Efficiency and Environmental Considerations Modern factories are increasingly focused on producing energy-efficient embroidery machines. Low energy consumption not only reduces operational costs but also aligns with global sustainability goals. Features such as energy-saving modes and eco-friendly materials are becoming standard in high-quality machines. This consideration is essential for businesses committed to reducing their carbon footprint, appealing to environmentally-conscious consumers. After-Sales Support and Training Comprehensive after-sales support elevates the buying experience significantly. Factories that provide extensive training sessions and 24/7 customer support ensure that businesses can swiftly address any operational challenges. Access to a knowledgeable support team facilitates smoother integration of new machines into existing operations, maximizing return on investment. Authoritative Resources and Networks Establishing connections with factories producing embroidery machines opens doors to authoritative networks. Leveraging insights and updates from industry leaders, forums, and exhibitions nurtures a deep understanding of the latest trends and innovations. Businesses can refine their production lines by incorporating cutting-edge techniques, thus remaining competitive and relevant in a rapidly evolving market. In conclusion, selecting embroidery machines from reputable factories involves a thorough evaluation of quality control, technological integration, customizability, durability, energy efficiency, support systems, and industry connections. Prioritizing these elements not only optimizes operational efficiency but also reassures stakeholders of the enterprise's dedication to exemplary crafting standards. As the market for embroidery goods continues to expand, investing in high-caliber machinery will invariably pave the way for sustained business success.

Latest news

-

Best Industrial Embroidery Machines For Sale | AI Tech

NewsAug.03,2025

-

Affordable 15-Needle Embroidery Machine with GPT-4 Turbo

NewsAug.02,2025

-

Affordable Commercial Embroidery Machines for Sale

NewsAug.01,2025

-

Top AI Embroidery Machine Manufacturers | GPT-4 Turbo Tech

NewsJul.31,2025

-

Affordable Computer Embroidery Machines | Best Prices

NewsJul.31,2025

-

Cheap T Shirt Printing Embroidery Machine with Multi Needle Efficiency

NewsJul.30,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy