Dec . 04, 2024 19:23 Back to list

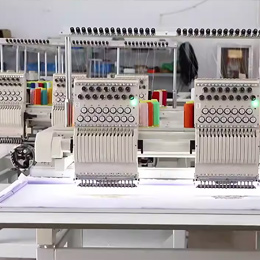

Industrial Embroidery Machines for Efficient Production in Manufacturing Facilities

The Role of Industrial Embroidery Machines in Modern Factories

In the fast-paced world of manufacturing, efficiency and precision are paramount. This is particularly true in the textile and apparel industries, where industrial embroidery machines have emerged as indispensable tools for factories looking to enhance productivity and product quality. These advanced machines have revolutionized the way designs are applied to fabric, offering a high degree of accuracy and speed that traditional methods simply cannot match.

Industrial embroidery machines are designed for bulk production, making them ideal for factories that require high-volume output without compromising on quality. Unlike home embroidery machines, industrial models can handle multiple needles and threads simultaneously, allowing for intricate designs to be stitched with precision. This capability is crucial in fulfilling large orders, whether for custom garments, promotional items, or branding materials such as uniforms and caps.

The Role of Industrial Embroidery Machines in Modern Factories

Moreover, industrial embroidery machines are equipped with advanced features that further enhance their functionality. For instance, many models come with automatic thread cutting, which reduces labor costs and speeds up the production process. Other features, such as color change capabilities and hooping systems, ensure that embroidery can be done seamlessly and without interruption. This automation not only boosts efficiency but also reduces the likelihood of human error, leading to a more consistent product.

embroidery machines industrial factories

Sustainability is another significant advantage offered by industrial embroidery machines. As consumers grow increasingly conscious of the environmental impact of their purchases, factories are under pressure to adopt more sustainable practices. Many modern embroidery machines are designed to minimize waste, using precise stitching techniques that reduce the amount of fabric left over after production. Furthermore, with the ability to produce high-quality items at a faster rate, factories can better align inventory levels with demand, reducing unsold stock and overall waste.

Training and expertise in operating these machines are vital. Modern industrial embroidery requires not just familiarity with the machinery, but also an understanding of design principles and fabric types. Factories often invest in training programs for their employees to ensure that they can fully leverage the capabilities of these machines. By fostering a skilled workforce, factories maximize the return on their investment in technology, enhancing both efficiency and product quality.

As markets become increasingly globalized, the demand for customized and branded products continues to grow. Industrial embroidery machines provide factories with the means to meet this demand effectively. Whether it is a local business looking to create unique merchandise or a multinational corporation needing consistent branding across different locations, these machines can deliver the required outcome. They enable factories to maintain a competitive edge by offering quick turnaround times, diverse design options, and the ability to cater to niche markets.

In conclusion, the advent of industrial embroidery machines has transformed the landscape of manufacturing within factories. Their ability to produce high-quality, customized embroidery at speed and scale has made them indispensable in today’s textile industry. As technology continues to evolve, it is likely that these machines will become even more advanced, offering new features and capabilities that further enhance production efficiency. For factories, investing in industrial embroidery machines is not just about keeping up with the latest trends; it is about positioning themselves at the forefront of a rapidly changing industry, ensuring that they remain competitive and meet the ever-growing demands of consumers. In a world where personalization and efficiency are increasingly valued, the role of these machines will only continue to expand, shaping the future of textile manufacturing.

-

Best Industrial Embroidery Machines For Sale | AI Tech

NewsAug.03,2025

-

Affordable 15-Needle Embroidery Machine with GPT-4 Turbo

NewsAug.02,2025

-

Affordable Commercial Embroidery Machines for Sale

NewsAug.01,2025

-

Top AI Embroidery Machine Manufacturers | GPT-4 Turbo Tech

NewsJul.31,2025

-

Affordable Computer Embroidery Machines | Best Prices

NewsJul.31,2025

-

Cheap T Shirt Printing Embroidery Machine with Multi Needle Efficiency

NewsJul.30,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy