Dec . 15, 2024 16:55 Back to list

large embroidery machine factory

Innovations and Trends in Large Embroidery Machine Factories

In the world of textile manufacturing, large embroidery machine factories play an integral role in producing high-quality embroidered materials that meet the diverse needs of the fashion and home decor industries. These factories harness advanced technology and innovative practices to streamline production processes while ensuring exceptional craftsmanship. This article delves into the workings of large embroidery machine factories, the latest trends shaping the industry, and the future of embroidery manufacturing.

The Role of Large Embroidery Machine Factories

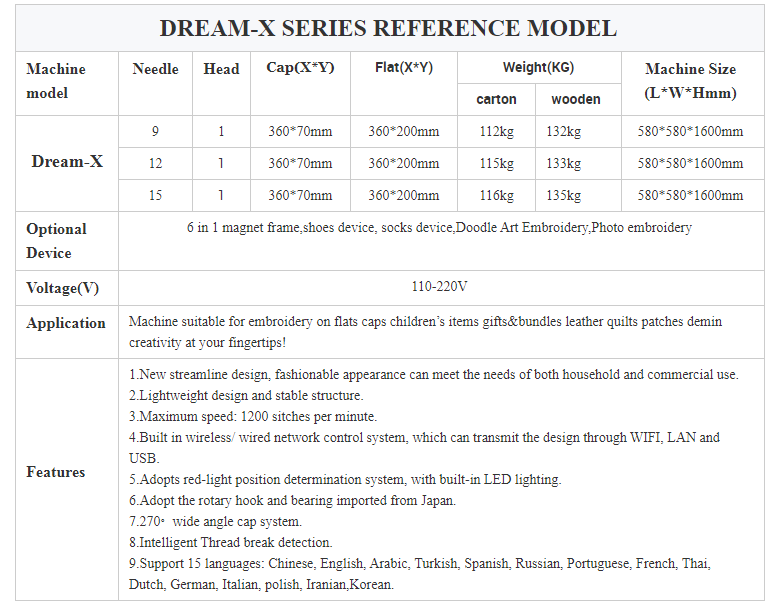

Large embroidery machine factories are designed to create intricate patterns and designs on various fabrics using sophisticated embroidery machines. These factories typically feature a variety of machines capable of performing different types of embroidery, including flat embroidery, 3D embroidery, and digital printing on textiles. The scale of operation allows them to cater to bulk orders, making them essential partners for clothing manufacturers, fashion brands, and promotional goods suppliers.

One of the key advantages of large factories is their capacity. Equipped with multiple high-speed embroidery machines, they can produce thousands of embroidered items in a single day. This mass production capability not only reduces the cost per unit but also ensures that clients can meet tight deadlines without compromising on quality. As fashion trends change rapidly, large embroidery factories are crucial in delivering timely and trendy products to the market.

Technological Advancements

Technological advancements have revolutionized the embroidery manufacturing process. Many large embroidery factories have adopted automated machines that incorporate artificial intelligence and machine learning. These technologies enable the machines to learn and adapt, optimizing their performance and reducing the likelihood of errors. For example, smart software can predict the maintenance needs of machines, thereby decreasing downtime and increasing productivity.

Additionally, the introduction of CAD (Computer-Aided Design) software allows designers to create and modify intricate patterns digitally. This software helps streamline the production process by generating precise specifications that can be directly fed into embroidery machines. As a result, the turnaround time from design to finished product has been significantly reduced.

Sustainability in Embroidery Manufacturing

large embroidery machine factory

As global awareness of environmental issues grows, many large embroidery machine factories are adopting sustainable practices. These include using eco-friendly threads and dyes, recycling fabric waste, and implementing energy-efficient machinery. Sustainable production not only appeals to environmentally conscious consumers but can also reduce operational costs in the long run.

Moreover, the trend of utilizing upcycled materials is gaining momentum in the embroidery industry. Factories are increasingly sourcing surplus textiles to create unique embroidered products. This approach not only helps to minimize waste but also leads to distinctive and artistic designs that resonate with consumers looking for something different.

Customization and Personalization

The demand for customized and personalized products is on the rise, and large embroidery machine factories are meeting this trend by offering bespoke services. With advancements in technology, consumers can now opt for personalized embroidery on various products, including clothing, accessories, and home goods. This trend has led to the development of small-batch production capabilities within large factories, allowing them to produce limited runs of customized items without sacrificing efficiency.

The integration of online platforms enables customers to design their embroidery patterns digitally, further enhancing the personalization experience. This direct-to-consumer approach not only boosts sales for factories but also fosters a stronger connection between brands and their customers.

Future Trends in Embroidery Manufacturing

Looking ahead, the embroidery manufacturing industry is poised for continuous growth and innovation. The integration of robotics and automation will likely play a significant role in enhancing operational efficiency. As factories strive for higher production speeds and lower costs, robotics can handle repetitive tasks, allowing skilled workers to focus on more complex design work and quality control.

Moreover, advancements in materials science are leading to the development of new fabrics that can accommodate different embroidery techniques. The emergence of smart textiles, which can change color or texture, presents exciting possibilities for innovative embroidery applications.

In conclusion, large embroidery machine factories are at the forefront of combining artistry with technology. By embracing innovation, sustainability, and customization, these factories are not only meeting the current demands of the market but are also shaping the future of embroidery manufacturing. As the industry continues to evolve, it promises to deliver exciting new products and experiences for consumers around the globe.

-

Affordable 15-Needle Embroidery Machine with GPT-4 Turbo

NewsAug.02,2025

-

Affordable Commercial Embroidery Machines for Sale

NewsAug.01,2025

-

Top AI Embroidery Machine Manufacturers | GPT-4 Turbo Tech

NewsJul.31,2025

-

Affordable Computer Embroidery Machines | Best Prices

NewsJul.31,2025

-

Cheap T Shirt Printing Embroidery Machine with Multi Needle Efficiency

NewsJul.30,2025

-

High-Quality T Shirt Embroidery Machine – Multi & 12/15 Needle Options

NewsJul.30,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy