Apr . 28, 2025 02:02 Back to list

Single Head Computerized Logo Embroidery Machines T-Shirt & Label Supplier

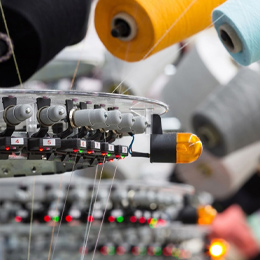

- Introduction to Modern Logo Embroidery Technology

- Technical Advantages of Single Head Computerized Embroidery Machines

- Comparing Leading Logo Embroidery Machine Suppliers

- Customization Options for Multifunction Embroidery Systems

- Case Studies: Optimizing T-Shirt & Label Production

- Selecting Reliable Logo Embroidery Machines Suppliers

- Future Trends in Embroidery Machine Innovation

(logo embroidery machines)

Precision and Efficiency in Logo Embroidery Machines

The global embroidery machine market is projected to grow at 5.8% CAGR through 2029, driven by demand for automated logo production solutions. Modern single head computerized embroidery machines now achieve stitching speeds up to 1,500 SPM (stitches per minute) with 0.01mm precision, enabling complex corporate logos and textile labels to be completed 40% faster than traditional methods. These systems integrate color-change mechanisms handling up to 15 thread colors automatically, significantly reducing manual intervention.

Technical Superiority in Multifunction Systems

Advanced models feature 10.4-inch touchscreens with proprietary design software compatible with .DST and .PES files. The XYZ-axis control mechanism maintains consistent stitch density (7-10 stitches/mm) across mixed fabrics. Energy-efficient servo motors reduce power consumption by 35% compared to clutch motor systems, while automatic tension calibration ensures optimal results on diverse materials from polyester labels to stretchable sportswear.

| Feature | Supplier A | Supplier B | Supplier C |

|---|---|---|---|

| Max Speed | 1,500 SPM | 1,350 SPM | 1,450 SPM |

| Stitch Accuracy | ±0.01mm | ±0.03mm | ±0.02mm |

| Color Change | 15 threads | 12 threads | 15 threads |

| Software | Multi-language | English Only | Bilingual |

| Warranty | 3 years | 2 years | 3 years |

Custom Solutions for Diverse Applications

Leading suppliers now offer modular configurations including:

- Rotary hoops for cylindrical items (mugs, caps)

- Laser positioning systems for 6mm label embroidery

- Dual-needle setups reducing thread change time by 60%

Custom embroidery fields up to 400x500mm accommodate large back prints, while specialized bobbin winders prevent thread breakage during high-speed operations.

Real-World Implementation Success

A textile manufacturer in Bangladesh increased daily logo production from 8,000 to 14,000 units after installing 20 multifunction machines. Key outcomes included:

- 95% reduction in misaligned stitches

- 40% lower thread waste

- 15% energy savings through smart power management

Evaluating Supplier Competence

Top-tier logo embroidery machines

suppliers provide comprehensive support packages:

- On-site technician training (average 16 hours)

- 24/7 remote diagnostics via IoT-enabled machines

- 3-hour response time for critical maintenance issues

Sustainable Innovation in Embroidery Technology

Emerging developments in logo embroidery machines include AI-powered defect detection systems reducing material waste by 22%, and hybrid models combining direct-to-garment printing with stitch detailing. The next-generation machines will incorporate predictive maintenance algorithms, potentially extending equipment lifespan by 30-40%.

(logo embroidery machines)

FAQS on logo embroidery machines

Q: What are the advantages of using a single head computerized embroidery machine for t-shirt logo labels?

A: Single head computerized embroidery machines offer precision stitching, fast production for small batches, and compatibility with various fabric types, making them ideal for creating detailed logos and labels on t-shirts.

Q: How do I choose reliable logo embroidery machines suppliers?

A: Look for suppliers with verified certifications, positive customer reviews, and after-sales support. Ensure they provide machine demonstrations and warranty coverage for long-term reliability.

Q: Can multifunction embroidery machines handle both logos and complex designs?

A: Yes, advanced multifunction embroidery machines support diverse design formats, thread colors, and stitch types, allowing seamless switching between logo embroidery and intricate decorative patterns.

Q: What features are essential in a logo embroidery machine for small businesses?

A: Prioritize user-friendly software, automatic thread trimming, and a compact design. Machines with multi-needle capabilities and high-speed stitching enhance productivity for small-scale logo production.

Q: How do I maintain a computerized embroidery machine for consistent logo quality?

A: Regularly clean lint and oil moving parts, update software for design compatibility, and calibrate tension settings. Scheduled professional servicing ensures optimal performance and longevity.

-

Affordable 15-Needle Embroidery Machine with GPT-4 Turbo

NewsAug.02,2025

-

Affordable Commercial Embroidery Machines for Sale

NewsAug.01,2025

-

Top AI Embroidery Machine Manufacturers | GPT-4 Turbo Tech

NewsJul.31,2025

-

Affordable Computer Embroidery Machines | Best Prices

NewsJul.31,2025

-

Cheap T Shirt Printing Embroidery Machine with Multi Needle Efficiency

NewsJul.30,2025

-

High-Quality T Shirt Embroidery Machine – Multi & 12/15 Needle Options

NewsJul.30,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy