Dec . 16, 2024 09:16 Back to list

Quilting and Embroidery Machine Manufacturing Industry Insights and Innovations

The Evolution and Importance of Quilting and Embroidery Machine Factories

In a world where personalization and creativity are increasingly valued, the demand for advanced textile processing technologies has surged. Quilting and embroidery are two such practices that have found their niche in both the commercial and consumer markets. The advent of quilting and embroidery machine factories has not only revolutionized the way these products are manufactured but also enabled artists, hobbyists, and businesses to bring their creative visions to life with precision and efficiency.

Historical Context

Quilting has been a cherished craft for centuries, originating from the necessity of creating warm bedding from scraps of fabric. It evolved into an art form, with intricate designs and patterns reflecting cultural heritage. Similarly, embroidery, with its roots in ancient civilizations, transformed from hand-stitched embellishments to machine-created masterpieces. The introduction of machines into these crafts marked a significant turning point, allowing for mass production and greater accessibility.

The Rise of Machine Factories

The rise of quilting and embroidery machine factories in the late 20th and early 21st centuries was driven by technological advancements and changing consumer preferences. Manufacturers began to recognize the potential of computer-aided design (CAD) software and automated sewing technologies. Factories sprung up around the world, particularly in regions known for textile production, such as Asia, North America, and Europe.

Types of Machines and Their Features

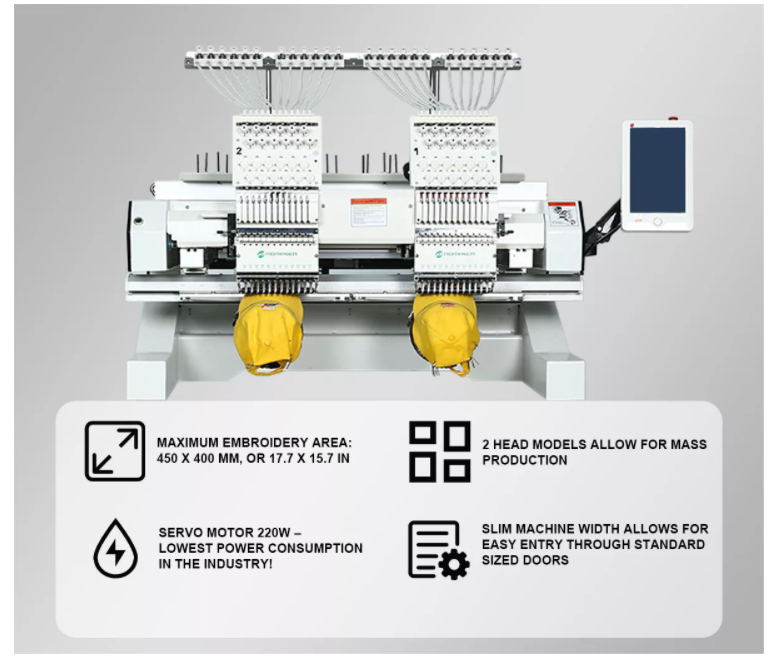

Modern quilting and embroidery machines come equipped with an array of features tailored to enhance productivity and creativity. These machines can range from basic models suitable for hobbyists to sophisticated industrial machines designed for large-scale production. Key features include

1. Automatic Stitching Many machines offer a selection of preset stitches for various quilting and embroidery designs, drastically reducing the time necessary for manual input.

2. Large Embroidery Areas Advanced machines provide ample space for larger projects, allowing crafters to work on quilts and designs without the limitations of smaller frames.

quilting and embroidery machine factories

4. Connectivity Many modern machines support USB and Wi-Fi connectivity, allowing users to download designs directly from the internet or transfer files from their computers seamlessly.

5. Embroidery Digitizing Software Some factories also offer accompanying software, enabling users to create custom designs and convert images into embroidery patterns easily.

Economic Impact

The establishment of quilting and embroidery machine factories has had a significant impact on the global economy. They create job opportunities not just in manufacturing but also in design, programming, and sales. Additionally, the factories foster innovation through competition.

As the demand for customizable products continues to rise, businesses increasingly rely on advanced machinery to meet consumer expectations. This has given birth to new niches within the market, such as personalized gifts and custom-designed apparel, further stimulating economic growth.

The Environmental Aspect

While the factories are pivotal to industrial efficiency, they also pose environmental challenges. The textile industry is notorious for its environmental footprint, and this has prompted many manufacturers to adopt sustainable practices. Factories are beginning to focus on eco-friendly production methods, such as using organic materials, reducing waste through efficient cutting techniques, and implementing water-saving technologies.

Future Trends

As technology continues to advance, we can expect the quilting and embroidery machine factories to evolve further. Innovations such as artificial intelligence in design, improved automation techniques, and enhanced user interface experiences will likely become more prevalent. Additionally, the integration of eco-friendly practices will be crucial as consumers increasingly seek sustainable options.

Conclusion

Quilting and embroidery machine factories play a crucial role in the modern textile industry. They not only enable the efficient production of intricate designs but also foster creativity among individuals and businesses alike. As technology progresses and sustainability becomes a priority, these factories will continue to adapt and thrive, ensuring that the art of quilting and embroidery remains vibrant and accessible for generations to come.

-

Affordable 15-Needle Embroidery Machine with GPT-4 Turbo

NewsAug.02,2025

-

Affordable Commercial Embroidery Machines for Sale

NewsAug.01,2025

-

Top AI Embroidery Machine Manufacturers | GPT-4 Turbo Tech

NewsJul.31,2025

-

Affordable Computer Embroidery Machines | Best Prices

NewsJul.31,2025

-

Cheap T Shirt Printing Embroidery Machine with Multi Needle Efficiency

NewsJul.30,2025

-

High-Quality T Shirt Embroidery Machine – Multi & 12/15 Needle Options

NewsJul.30,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy