Dec . 13, 2024 16:26 Back to list

Custom T-Shirt Printing and Embroidery Machine Manufacturer for Quality Apparel Production

The Evolution of T-Shirt Printing and Embroidery Machines in Modern Factories

In today's fast-paced fashion industry, t-shirt printing and embroidery machines play a crucial role in the production of custom apparel. As consumer demand for unique and personalized clothing continues to rise, the advancements in technology have transformed how factories approach the manufacturing of these items. This article explores the significance of t-shirt printing and embroidery machines, highlighting their evolution and impact on factory productivity and the broader garment sector.

The Importance of Customization

Customization is a key trend in the clothing market. Consumers increasingly seek out personalized apparel to express their individuality and creativity. T-shirt printing and embroidery machines facilitate this demand by allowing factories to produce a wide range of designs, from intricate logos to vibrant images, all tailored to the customer’s specifications. As a result, businesses can offer products that stand out in a saturated market, enhancing customer satisfaction and loyalty.

Historical Context

Historically, t-shirt production involved tedious manual processes that were time-consuming and labor-intensive. Early printing methods, such as screen printing, required skilled artisans to create each design individually. The advent of technology brought about a significant shift in this laborious process. Modern printing techniques, including direct-to-garment (DTG) printing and heat transfer vinyl, revolutionized how designs are applied to fabrics, drastically reducing production time and costs.

Similarly, embroidery has evolved from hand-sewn techniques to sophisticated machines capable of executing complex patterns with remarkable precision. These advancements have made it possible for factories to scale their operations efficiently, maintaining high standards of quality while meeting the growing demands of consumers.

Advancements in Technology

The latest t-shirt printing and embroidery machines incorporate cutting-edge technology, including computer-aided design (CAD) software, which allows designers to create and manipulate designs digitally before production. This integration streamlines the design process, ensuring that the final product matches the client’s vision.

t shirt printing embroidery machine factory

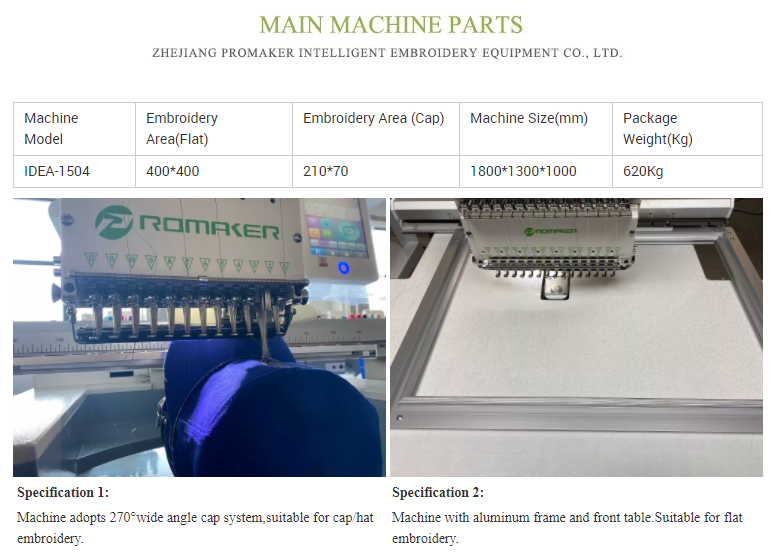

Moreover, modern embroidery machines are equipped with multi-needle systems, automatic thread cutting, and color-changing capabilities. These features enable factories to run operations with minimal human intervention, thus reducing the likelihood of errors and increasing overall output. The ability to run multiple jobs simultaneously has proven invaluable, especially during peak seasons or for large orders.

Sustainability in Production

As the fashion industry grapples with sustainability challenges, t-shirt printing and embroidery technology have adapted to address these concerns. Many manufacturers are now utilizing eco-friendly inks and organic fabrics, which not only appeal to environmentally conscious consumers but also reduce the overall carbon footprint of the production process. Additionally, machines that optimize fabric use help minimize waste, further contributing to a more sustainable approach in apparel manufacturing.

The Future of T-Shirt Printing and Embroidery Machines

Looking ahead, the future of t-shirt printing and embroidery machines in factories seems promising. As artificial intelligence and automation technologies continue to evolve, we can expect even greater efficiencies in production. Innovations such as automated inventory management, predictive maintenance for machinery, and data analytics will empower factories to optimize their workflows and respond quickly to market trends.

Furthermore, with the rise of e-commerce and the demand for quick turnaround times, manufacturers may increasingly adopt on-demand production models. This approach allows for the creation of t-shirts only when orders are placed, thereby reducing inventory costs and minimizing unsold stock.

Conclusion

In conclusion, t-shirt printing and embroidery machines have transformed the garment manufacturing landscape, driving efficiency, customization, and sustainability. As technology advances and consumer preferences continue to evolve, factories must adapt to stay competitive. Embracing these innovations will not only enhance productivity but also ensure that they meet the ever-changing demands of the global market, ultimately leading to a more dynamic and responsive apparel industry.

-

Affordable Commercial Embroidery Machines for Sale

NewsAug.01,2025

-

Top AI Embroidery Machine Manufacturers | GPT-4 Turbo Tech

NewsJul.31,2025

-

Affordable Computer Embroidery Machines | Best Prices

NewsJul.31,2025

-

Cheap T Shirt Printing Embroidery Machine with Multi Needle Efficiency

NewsJul.30,2025

-

High-Quality T Shirt Embroidery Machine – Multi & 12/15 Needle Options

NewsJul.30,2025

-

High-Efficiency Computerized T Shirt Embroidery Machine for Custom Apparel

NewsJul.29,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy