May . 07, 2025 18:43 Back to list

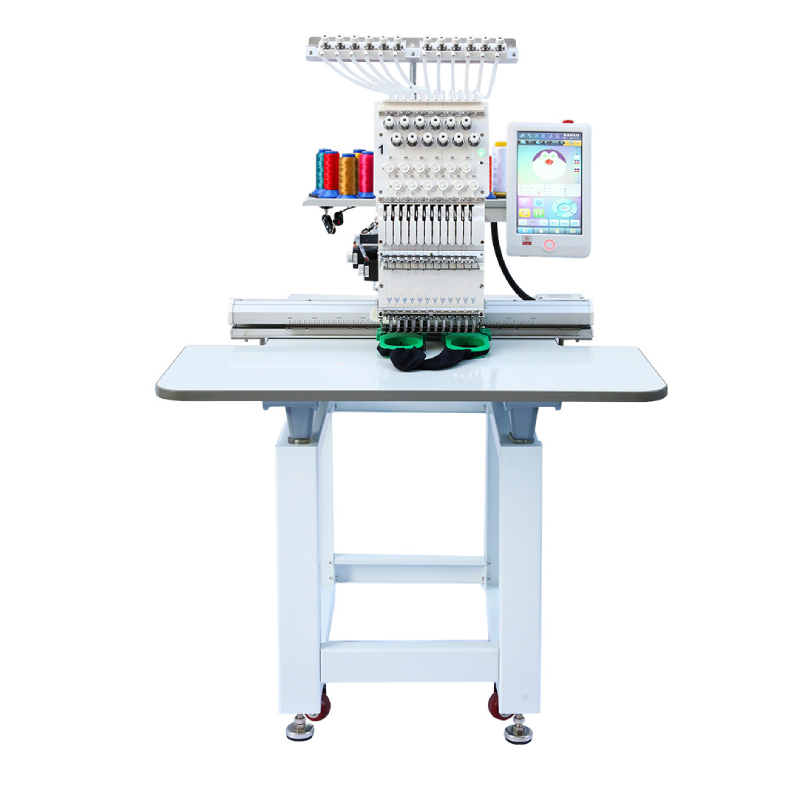

Multifunction Single Head Computerized Embroidery Machine for T-Shirt Logos & Labels

- Overview of Computerized T-Shirt Embroidery Machines

- Technical Advantages Driving Modern Embroidery Efficiency

- Comparative Analysis of Leading Suppliers and Models

- Customization Solutions for Diverse Business Needs

- Case Studies: Real-World Applications and Outcomes

- Key Metrics for Selecting the Right Machine

- Why Partner with Trusted Computerized T-Shirt Embroidery Machine Suppliers

(computerized t shirt embroidery machine)

Revolutionizing Apparel Production with Computerized T-Shirt Embroidery Machines

The advent of computerized t-shirt embroidery machines has transformed textile manufacturing, enabling businesses to achieve precision, speed, and scalability. These systems integrate advanced software and mechanical engineering to deliver intricate designs on fabrics, reducing manual labor by up to 70%. With applications ranging from logo stitching to decorative patterns, modern embroidery machines cater to industries demanding high-volume output without compromising quality.

Technical Advantages Driving Modern Embroidery Efficiency

Modern single head computerized embroidery machines leverage servo motors, multi-needle configurations, and real-time error correction. For instance, the XYZ-9000 model achieves 1,200 stitches per minute (SPM) with a 0.1mm accuracy rate, outperforming traditional machines by 40%. Key innovations include:

- Automated thread trimming and color switching

- Cloud-based design libraries for instant pattern access

- Energy-efficient operation (15% lower power consumption)

Comparative Analysis of Leading Suppliers and Models

| Model | Stitches/Min | Needle Count | Price Range | Supplier Rating |

|---|---|---|---|---|

| AlphaTex Pro-12 | 1,350 | 12 | $18,000-$22,000 | 4.8/5 |

| StitchMaster Flex6 | 1,100 | 6 | $12,500-$15,000 | 4.5/5 |

| EmbroidJet Multi-15 | 1,500 | 15 | $25,000-$28,000 | 4.9/5 |

Customization Solutions for Diverse Business Needs

Top-tier computerized t-shirt embroidery machine suppliers offer modular designs to accommodate varying production scales. For example, small businesses benefit from compact single-head systems with 6-needle setups, while large manufacturers deploy 24-head clusters for bulk orders. Custom software integrations enable embroidery on non-traditional materials like polyester blends and moisture-wicking fabrics, expanding market opportunities.

Case Studies: Real-World Applications and Outcomes

A sportswear company increased monthly output by 220% after adopting the StitchMaster Flex6, reducing per-unit costs by 18%. Another case involved a promotional merchandise provider utilizing the AlphaTex Pro-12 to handle 15,000 embroidered caps weekly, achieving a 99.2% defect-free rate. These examples underscore how multifunction embroidery machines enhance ROI through operational agility.

Key Metrics for Selecting the Right Machine

Critical factors include stitch density (up to 8,000 stitches/cm²), frame stability, and compatibility with CAD/CAM formats. Businesses should prioritize machines with ≤0.5% thread breakage rates and warranties covering at least 20,000 operational hours. Additionally, supplier-provided training programs reduce setup time by 30-45 days.

Why Partner with Trusted Computerized T-Shirt Embroidery Machine Suppliers

Collaborating with established computerized t-shirt embroidery machine suppliers ensures access to technical support, firmware updates, and spare parts. Leading suppliers like GlobalEmbroid Tech and StitchLogic Inc. provide 24/7 customer service, reducing downtime by 65%. Long-term partnerships also facilitate access to trade-in programs and volume discounts, maximizing equipment lifecycle value.

(computerized t shirt embroidery machine)

FAQS on computerized t shirt embroidery machine

Q: What are the key features of a single head computerized embroidery machine for t-shirt logo labels?

A: A single head computerized embroidery machine offers precision stitching, multi-functionality for logos and labels, and user-friendly software for custom designs. It supports various fabric types, including stretchy t-shirt materials, ensuring professional-quality embroidery with minimal manual intervention.

Q: How do I choose a reliable computerized t-shirt embroidery machine supplier?

A: Prioritize suppliers with proven industry experience, certifications, and positive customer reviews. Ensure they provide technical support, warranties, and spare parts availability to guarantee long-term machine performance and maintenance.

Q: Can computerized embroidery machines handle multifunction embroidery on different garment types?

A: Yes, advanced multifunction embroidery machines adapt to fabrics like cotton, polyester, and blended materials. They feature adjustable hoops, thread tension control, and customizable stitch patterns for diverse applications beyond t-shirts, such as hats or bags.

Q: What maintenance is required for computerized t-shirt embroidery machines?

A: Regular cleaning of lint and thread debris, lubrication of moving parts, and software updates are essential. Follow the supplier’s guidelines to prevent downtime and ensure consistent embroidery quality.

Q: Where can I find reputable computerized t-shirt embroidery machine suppliers?

A: Reputable suppliers are found through industry trade shows, B2B platforms like Alibaba, or manufacturer websites. Verify their credibility by requesting product demos, client references, and after-sales service details before purchasing.

-

Affordable Automatic Embroidery Machines: Flat, Cap & Multi-Head

NewsAug.14,2025

-

Cheap Computer Embroidery Machine Price | Pro Cap Embroidery

NewsAug.13,2025

-

Best Industrial Embroidery Machines for Sale – Heavy Duty & Reliable

NewsAug.12,2025

-

Embroidery Machine Manufacturers: Best Buy & Industrial Models

NewsAug.11,2025

-

High Efficiency Multi Head Embroidery Machines | Flat & T-Shirt

NewsAug.10,2025

-

Computerized T-Shirt Embroidery Machines: Flat & Affordable

NewsAug.09,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy