jún . 06, 2025 00:41 Back to list

Best Computer Embroidery Machines - Low Prices & Reliable Suppliers

- Factors influencing embroidery machine investment decisions

- Technical advantages of modern computerized units

- Price segmentation across machine categories

- Supplier comparison tables with detailed specifications

- Service expectations from leading equipment providers

- Industry-specific application case studies

- Strategies for optimal machine selection

(embroidery machine price)

Understanding Embroidery Machine Price Determinants

Embroidery machine prices range from $3,000 for basic single-head units to over $160,000 for industrial multi-head systems. The primary price determinants include stitch speed (up to 1,500 SPM on premium models), embroidery head count (1 to 56 heads), stitch density capacity (0.3mm minimum on advanced machines), and software sophistication. Premium manufacturers like Tajima and Barudan incorporate advanced features such as automatic thread trimming, tension control with ±0.5g precision, and 3D visual preview systems that add 25-40% to the base price. A recent Textile Machinery Association report indicates that computerized embroidery machine price

averages rose 8.3% annually since 2020, reflecting demand for automated production solutions.

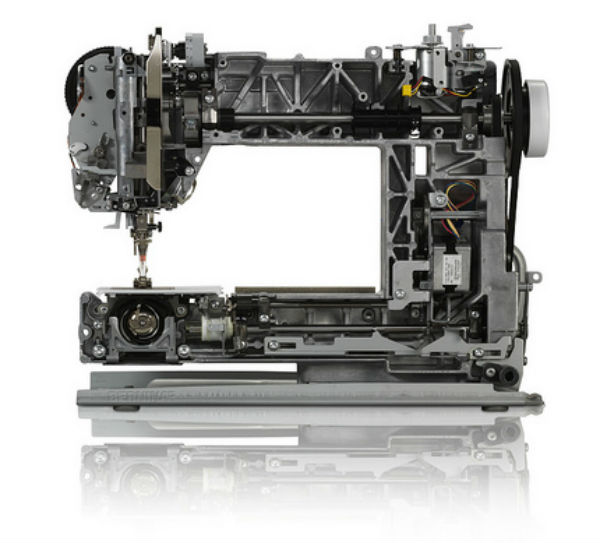

Technological Evolution in Modern Embroidery Systems

Modern computer embroidery machines integrate features providing tangible ROI within 12-18 months for most businesses. Precise control systems maintain thread tension accuracy within 0.2cN, reducing material waste by up to 30% compared to conventional machines. Direct-drive motors eliminate belt slippage issues while lowering maintenance costs by 45%. The latest machines feature 15-inch touchscreen interfaces running Linux-based embroidery software capable of processing 10,000+ stitch files without conversion lag. Industry leader Melco's systems incorporate artificial intelligence that predicts thread breaks with 92% accuracy and self-calibrates tension parameters based on thread material composition.

Price Segmentation Across Machine Categories

Embroidery equipment falls into three distinct price brackets with corresponding capabilities:

Commercial-grade machines ($3,000-$18,000): Offer 400-800 SPM speeds with 0.5mm precision on single-head units. Suitable for small boutiques handling up to 100 pieces daily.

Semi-industrial systems ($20,000-$60,000): Operate at 850-1,200 SPM with auto-trimming features on 4-6 head configurations that triple output efficiency.

Industrial installations ($65,000-$160,000+): Deliver production volumes exceeding 1,000 pieces daily via 12-56 head arrays working simultaneously at 1,500 SPM with ±0.05mm positioning accuracy.

Computerized Embroidery Machine Supplier Comparison

| Supplier | Head Options | Stitch Speed | Price Range | Warranty | Setup Time |

|---|---|---|---|---|---|

| Tajima (Japan) | 1-56 heads | 1,400 SPM | $55,000-$165,000 | 5 years | 1-3 days |

| Barudan (Japan) | 1-36 heads | 1,350 SPM | $48,000-$145,000 | 4 years | 2-4 days |

| Brother (Global) | 1-16 heads | 1,200 SPM | $26,000-$98,000 | 3 years | 8-10 hours |

| Melco (USA) | 1-24 heads | 1,250 SPM | $32,000-$112,000 | 3 years | 12-18 hours |

Leading computer embroidery machine price suppliers include Tajima and Barudan with premium pricing reflecting precision engineering, while Brother offers competitive entry points into mid-range production capability. North American suppliers typically provide shorter setup durations due to regional distribution centers.

Service Expectations from Equipment Suppliers

Reputable computer embroidery machine price service packages offer comprehensive support exceeding basic warranty terms. Premium suppliers provide next-business-day onsite response with technicians carrying proprietary replacement components. Industry surveys indicate 91% of enterprises prioritizing suppliers offering remote diagnostics through encrypted network connections with 24/7 technical support centers. Standard service contracts typically include:

- Unlimited software upgrades for the machine's operational life

- Quarterly preventive maintenance visits with calibration reports

- Loaner equipment during extended repairs

- Comprehensive operator training programs (40-60 contact hours)

Leading suppliers maintain regional spare part inventories enabling same-day delivery for critical components worth 5-9% of the machine's base price annually.

Industry Application Success Stories

Uniform manufacturers achieve 18-month ROI using 6-head configurations producing over 350,000 embroidered garments annually. A Midwest sports apparel company serving collegiate markets increased production 430% after implementing Tajima multi-head systems with automatic cap hoops. Luxury automotive interior specialists reduced lead times from 14 days to 48 hours using Barudan machines equipped with specialized shuttle hooks for leather substrate penetration. Digitization specialists emphasize selecting machines matching specific application requirements rather than maximum stitch speeds alone.

Securing Optimal Computer Embroidery Machine Price Value

Successful acquisition balances initial computer embroidery machine price against lifetime operational costs. Production analysis indicates that investing 25-35% above base price for auto-trimming capabilities delivers 300% productivity gains for medium-volume enterprises. Evaluation should include onsite demonstrations with proprietary designs to verify stitch consistency across seam transitions. Leading computer embroidery machine price suppliers extend customized financing plans with 60-month terms, reducing initial capital impact. Projections show that multi-unit installations utilizing premium machines achieve payback 17% faster than economy alternatives due to reduced thread consumption and consistent output quality.

(embroidery machine price)

FAQS on embroidery machine price

Q: What affects embroidery machine price?

A: Embroidery machine prices depend on features like size and automation level. Computer models typically cost more than manual ones. Brand reputation and included accessories also influence the final price.

Q: How do I find reliable computer embroidery machine price suppliers?

A: Search online directories or industry marketplaces for vetted computer embroidery machine price suppliers. Verify reviews and request quotes from multiple sources. Choosing certified suppliers ensures quality support and fair pricing.

Q: Can I compare computer embroidery machine price suppliers easily?

A: Yes, compare computer embroidery machine price suppliers using online tools or B2B platforms. Evaluate quotes based on machine specs, warranties, and shipping terms. Opting for established suppliers reduces risks in procurement.

Q: What does computer embroidery machine price service include?

A: Computer embroidery machine price service often covers installation, training, and maintenance. Packages may include technical support or extended warranties for added value. Always clarify service details before purchase.

Q: Is it better to buy from one or multiple computer embroidery machine price suppliers?

A: Assess single vs. multiple computer embroidery machine price suppliers based on your needs. Multiple suppliers offer competitive prices and diverse options, while one may simplify support. Consider costs, delivery speed, and reliability.

-

6 Head Embroidery Machine for Professional T-Shirt Embroidery

NewsJul.25,2025

-

High-Efficiency Computerized T Shirt Embroidery Machine for Custom Apparel

NewsJul.24,2025

-

High-Speed 12 Needle Embroidery Machine for T-Shirts & Custom Apparel

NewsJul.23,2025

-

High-Efficiency Multi Head Embroidery Machine for Custom Apparel

NewsJul.22,2025

-

Automatic Embroidery Machine: Fast, Affordable Multi-Head Solutions

NewsJul.22,2025

-

Cheap Computer Embroidery Machine Price | Pro & Cap Embroidery Deals

NewsJul.21,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy