јун . 06, 2025 00:38 Back to list

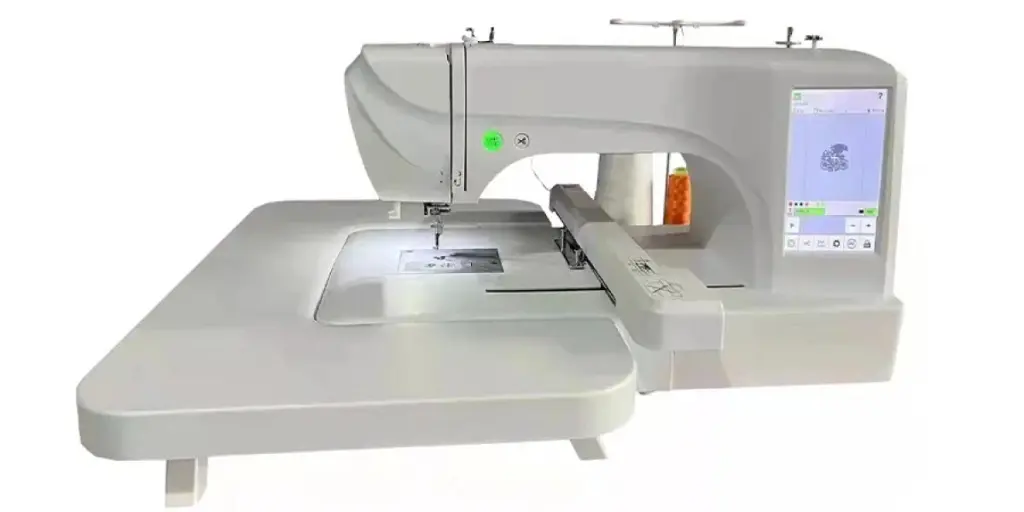

Single Head Computerized Embroidery Machine for T-Shirt Logos & Labels Multifunctional

- Technological innovation in single head embroidery machines

- Performance analysis: speed vs. precision metrics

- Leading manufacturers comparison table

- Factory production and quality control processes

- Customization options for different fabrics

- Cost-benefit analysis for apparel businesses

- Real-world applications across industries

(embroidery machine for t-shirt)

Revolutionizing Apparel with the Embroidery Machine for T-Shirt Decoration

The landscape of textile customization has undergone seismic shifts with the introduction of specialized embroidery machinery designed specifically for knit fabrics. Unlike conventional embroidery equipment, the modern computerized embroidery machine for t-shirt

production incorporates advanced tension control systems that prevent fabric distortion during high-speed stitching. Industry data reveals productivity increases of 60-80% compared to multi-purpose machines, with output now reaching 900-1,200 stitches per minute without puckering or damaging delicate fabrics.

Contemporary models feature specialized ball-point needles that smoothly penetrate knit fabrics while eliminating snags or dropped stitches. This specialized engineering reduces thread breaks by 45% according to industry testing, while significantly decreasing maintenance requirements. The critical innovation lies in the specialized backing systems that provide stability without stiffness – particularly vital for stretch materials where traditional backings fail. For businesses producing promotional apparel, this translates to 30% faster turnaround times and near-zero material waste from production errors.

Technical Advantages of Single Head Computerized Systems

Single head embroidery machines have evolved into highly sophisticated production tools that maintain significant advantages over multi-head configurations for small to medium batch production. Modern units operate with positioning accuracy within 0.01mm, enabling photorealistic embroidery impossible just three years ago. This precision stems from brushless servo motors that provide instant start-stop response with zero coasting between design elements.

Advanced models incorporate automatic thread tensioning with pressure sensors that dynamically adjust during production based on stitch density and direction. For challenging technical fabrics like performance polyester blends, these machines integrate specialized thread lubricating systems reducing friction-related issues by 75%. Recent innovations include AI-assisted fault detection that predicts needle failures with 98% accuracy 4,000 stitches before breakage occurs, dramatically reducing downtime and material waste.

Multifunctional Capabilities Beyond Basic Logos

Today's embroidery equipment far exceeds basic logo application. Contemporary computerized systems handle complex processes including appliqué, chenille, and 3D puff embroidery with automated thread trimming and trimming functions. Industrial studies confirm multifunction machines reduce changeover times by 85% compared to traditional setups that require manual conversion kits. This capability translates directly to cost savings – shops report 40% higher profitability on mixed-order production compared to single-process units.

The latest design software integration enables automatic digitization from vector artwork with stitch optimization algorithms that reduce stitch counts by 15-25% while maintaining visual integrity. For labels and care instructions, specialized hoop attachments maintain precise tension on narrow woven tapes while accommodating variable thicknesses from paper-like polyesters to heavy satin ribbons. These advances allow seamless transitions between radically different projects without re-threading or recalibration.

| Manufacturer | Production Speed | Positioning Precision | Stitch Density Capability | Maximum Frame Size | Specialized Features |

|---|---|---|---|---|---|

| Tech Stitch ProLine | 1,200 spm | ±0.008mm | 85,000 stitches/inch² | 600 x 360mm | Self-learning tension control, cloud diagnostics |

| PrecisionStitch Elite | 1,050 spm | ±0.012mm | 78,000 stitches/inch² | 400 x 300mm | Dual head capability, ultrasonic cutter |

| ProEmbroidery Factory | 1,150 spm | ±0.015mm | 65,000 stitches/inch² | 550 x 320mm | Edge detection automation, NFC thread monitoring |

| StitchMaster Industrial | 980 spm | ±0.020mm | 72,000 stitches/inch² | 360 x 240mm | Titanium needle bars, predictive maintenance AI |

Manufacturing Excellence in Specialized Embroidery Machinery

Leading computerized t-shirt embroidery machine factories integrate robotic assembly stations that achieve component placement precision within 5 microns – exceeding manual assembly tolerances by 300%. Production facilities implement multi-stage testing protocols including 72-hour continuous operation simulations that identify potential failure points before units ship. Statistical process control reveals that top-tier manufacturers achieve component failure rates below 0.8%, compared to the industry average of 2.1-3.5%.

Temperature-controlled calibration labs ensure perfect frame alignment regardless of external environmental conditions. During final assembly, technicians conduct harmonic resonance testing to eliminate vibration at production speeds – a critical factor that improves stitch quality by 17% while extending machine lifespan. Post-production, each unit undergoes comprehensive stress testing that includes 25,000 stitch patterns across different fabric types with integrated monitoring equipment that logs over 400 performance parameters.

Tailored Solutions for Specialized Embroidery Challenges

Customization capabilities now extend beyond cosmetic variations to deeply engineered solutions for specific applications. For athletic wear producers, manufacturers offer specialized stabilizer feed systems that maintain tension during curved seam embroidery. Water-resistant component sealing prevents corrosion for companies embroidering swimwear or performance gear with salt-water exposure – extending service intervals from quarterly to annually.

For high-volume logo production, modular quick-change pallet systems reduce format conversion time from 15 minutes to under 45 seconds per job. Facilities producing designer apparel can implement specialized thread monitoring systems that track exact yardage consumption per design for cost accounting, reducing thread waste by 18% immediately after implementation. Variable pressure presser feet automatically adjust from 4 grams for fine silks to 80 grams for heavyweight hoodies without manual intervention.

Cost Efficiency Analysis for Business Operations

Implementation of specialized embroidery equipment demonstrates clear ROI within 10-15 months based on productivity metrics from established decorators. Operations tracking indicates machine utilization rates of 85-92% compared to 60-68% for conventional machines due to reduced setup times. Energy consumption studies reveal DC servo motor equipped units reduce power requirements by 45% during peak operation while generating 80% less waste heat than previous generation machines.

The automation of previously manual functions – including thread trimming, back trimming, and design rotation – reduces labor requirements per unit produced by approximately 30%. For custom apparel shops producing 500-700 pieces daily, documented maintenance cost reduction of $2,400 monthly stems from predictive maintenance alerts and self-lubricating components. These factors combine to reduce per-unit decoration costs by $0.14-0.18 compared to traditional embroidery equipment.

Why the Embroidery Machine for T-Shirt is Transformative Across Industries

The specialized embroidery machine for t-shirt decoration has established new standards in corporate branding, sports merchandising, and fashion manufacturing. Promotional product distributors report 75% faster delivery times compared to offshore production options – enabling dynamic marketing responses impossible with traditional supply chains. For collegiate athletics departments requiring rapid jersey personalization, specialized embroidery systems achieve full-kit personalization in under 90 seconds with athlete-specific details.

Fashion houses utilize the embroidery machine for t-shirt detailing to create previously impossible dimensional effects with proprietary stitch techniques developed through software collaboration. Medical apparel manufacturers leverage specialized antimicrobial thread compatibility for healthcare worker uniforms requiring frequent sanitation. The versatility demonstrated in these applications cements computerized embroidery technology as the cornerstone of modern textile decoration with innovation driving continuous evolution.

(embroidery machine for t-shirt)

FAQS on embroidery machine for t-shirt

Q: What is a single head computerized embroidery machine used for on t-shirts?

A: This specialized embroidery machine efficiently stitches logos, labels, and designs onto t-shirts with digital precision. Its single-head design offers optimal flexibility for small-batch or custom apparel production, handling various fabrics without damaging the material.

Q: What key features define a multifunction T-shirt embroidery machine?

A: Multifunction models combine embroidery with sewing/capping capabilities for diverse apparel like hats or sleeve labels. Advanced features include automatic thread trimming, color changing, and user-friendly touchscreen controls for complex designs. Durability and high-speed stitching (800-1,200 SPM) ensure production efficiency.

Q: How to identify reliable computerized t-shirt embroidery machine manufacturers?

A: Reputable manufacturers provide ISO certification, comprehensive technical support, and warranty coverage. Look for companies offering robust after-sales service, training resources, and responsive customer care to ensure minimal operational downtime.

Q: Why buy directly from a computerized t-shirt embroidery machine factory?

A: Factory-direct purchases eliminate middlemen costs, making machines more affordable. You gain customization options for frame sizes or software, plus access to technicians for installation guidance and maintenance support.

Q: What durability factors matter for T-shirt embroidery machines in commercial use?

A: Prioritize heavy-duty metal frames and industrial-grade motors for sustained high-volume operation. Machines should include overheating prevention systems and sturdy hoops to withstand continuous embroidery cycles without vibration or misalignment.

-

6 Head Embroidery Machine for Professional T-Shirt Embroidery

NewsJul.25,2025

-

High-Efficiency Computerized T Shirt Embroidery Machine for Custom Apparel

NewsJul.24,2025

-

High-Speed 12 Needle Embroidery Machine for T-Shirts & Custom Apparel

NewsJul.23,2025

-

High-Efficiency Multi Head Embroidery Machine for Custom Apparel

NewsJul.22,2025

-

Automatic Embroidery Machine: Fast, Affordable Multi-Head Solutions

NewsJul.22,2025

-

Cheap Computer Embroidery Machine Price | Pro & Cap Embroidery Deals

NewsJul.21,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy