ነሐሴ . 11, 2025 10:40 Back to list

Embroidery Machine Manufacturers: Best Buy & Industrial Models

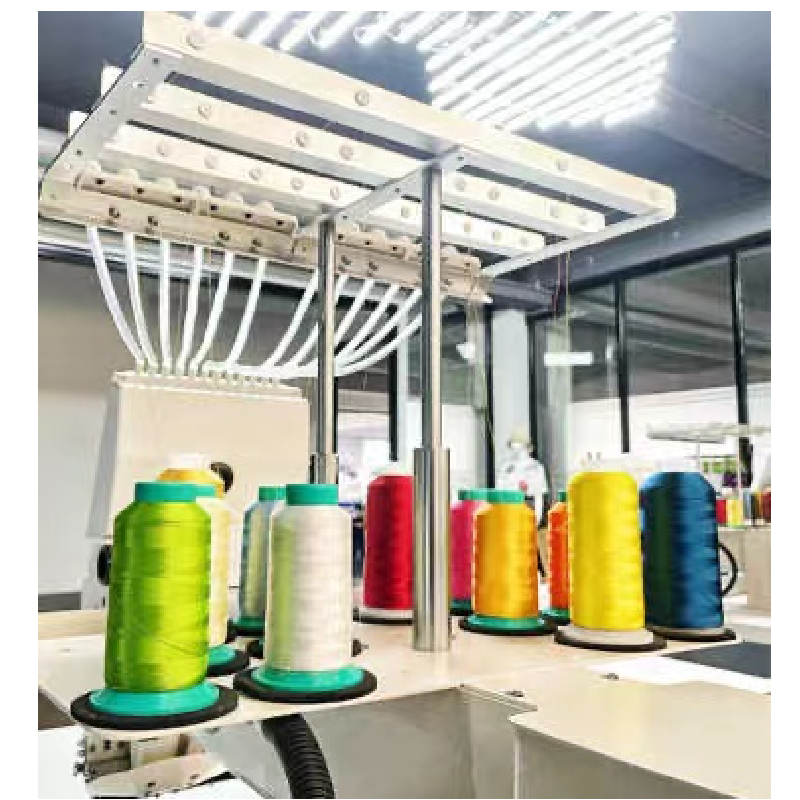

Unveiling the Precision and Power of Industrial Embroidery Machines

The textile and apparel industry continually seeks advanced manufacturing solutions to meet the escalating demands for customization, quality, and efficiency. At the heart of this evolution are sophisticated industrial embroidery machines. As leading embroidery machine manufacturers, we understand the critical role these machines play in modern production lines. Our focus remains on delivering innovative technology that pushes the boundaries of design and productivity, particularly with multi-head, high-needle count systems. These machines are engineered to cater to high-volume production while maintaining impeccable stitch quality and operational reliability, crucial for competitive B2B environments.

The global embroidery machine market is projected to grow significantly, driven by trends in personalized apparel, home furnishings, and branded promotional products. Businesses are increasingly investing in robust, high-performance equipment to enhance their capabilities and reduce lead times. Our flagship product, the Good quality factory use Multi heads 15 needles embroidery machines industrial computerized, embodies this commitment to excellence, offering unparalleled precision, speed, and versatility for demanding industrial applications.

The Core of Craftsmanship: Manufacturing Excellence in Embroidery Machines

The manufacturing process of industrial embroidery machines demands meticulous attention to detail and advanced engineering. As experienced and authoritative embroidery machine manufacturers, we integrate several high-precision steps to ensure the durability, accuracy, and longevity of our products.

Materials and Component Sourcing:

Our machines utilize high-grade materials, including aerospace-grade aluminum alloys for lightweight yet rigid frames, and hardened steel for critical moving parts like shafts, cams, and gears. These materials are selected for their exceptional strength-to-weight ratio, wear resistance, and ability to withstand continuous high-speed operation. Components such as motors, bearings, and electronic control systems are sourced from globally recognized suppliers, ensuring reliability and long-term performance.

Precision Manufacturing Processes:

- CNC Machining: Core structural components and intricate mechanical parts are produced using state-of-the-art Computer Numerical Control (CNC) machining centers. This ensures unparalleled precision, often within microns, crucial for smooth operation and stitch accuracy.

- Laser Cutting: Sheet metal parts for the machine's casing and internal brackets are cut with high-precision lasers, guaranteeing clean edges and exact dimensions for perfect fit and finish.

- Robotic Assembly: Certain repetitive and precision-critical assembly tasks are performed by robots to eliminate human error and ensure consistency across all units. This includes the delicate alignment of multi-head systems and needle bars.

- Surface Treatment: Components undergo various surface treatments, such as anodizing for aluminum parts and specialized coatings for steel, to enhance corrosion resistance and reduce friction, thereby extending the machine's operational life.

Rigorous Quality Control and Standards:

Every machine undergoes a comprehensive series of inspections and tests. Our quality management system is certified to ISO 9001 standards, ensuring consistent quality from design to delivery. Key inspection points include dimensional accuracy of parts, functional testing of sub-assemblies, and exhaustive full-machine operational tests. Performance metrics such as stitch quality, maximum operating speed (SPM), vibration levels, and noise emissions are carefully monitored against strict internal and industry benchmarks (e.g., ANSI standards for mechanical integrity). This rigorous process ensures a product lifespan exceeding typical industry expectations, often 10-15 years with proper maintenance.

Applicable Industries and Advantages:

Our industrial computerized embroidery machines are indispensable across a broad spectrum of industries, including:

- Apparel Manufacturing: For mass production of embroidered garments, logos, and intricate designs.

- Home Textiles: Embellishing bedding, curtains, towels, and upholstery with decorative patterns.

- Promotional Products: Customizing caps, bags, uniforms, and corporate merchandise with branding.

- Fashion Design Houses: Creating unique, high-end embroidered fabrics and couture pieces.

- Automotive Interior Embellishment: Adding refined embroidery to car seats and interior panels.

The advantages in these typical application scenarios are profound:

- High Precision: Achieving intricate designs with exceptional detail and consistent stitch quality across all heads.

- High Speed & Multi-Head Efficiency: Dramatically increasing production output compared to single-head machines, crucial for meeting tight deadlines.

- Versatile Application Range: Handling a wide array of fabrics and embroidery techniques, from delicate silks to heavy denim.

- Robust Construction: Designed for continuous industrial use, ensuring minimal downtime and extended operational life.

- Reduced Waste: Advanced software and precise mechanics minimize thread breaks and material spoilage, contributing to cost savings.

Technological Parameters & Performance Insights

Understanding the technical specifications is paramount for industrial buyers. Our Good quality factory use Multi heads 15 needles embroidery machines industrial computerized is engineered for peak performance and reliability.

Key Specifications and Expertise:

- Needle Count: 15 needles per head allows for a vast color palette without frequent thread changes, significantly boosting efficiency for multi-color designs.

- Number of Heads: Available in multiple configurations (e.g., 2, 4, 6, 8, 10, 12, 16, 20 heads), enabling simultaneous production of identical or different designs across multiple items, dramatically increasing output.

- Max Speed: Typically ranging from 850 to 1200 stitches per minute (SPM), ensuring rapid production cycles. Higher SPM directly translates to greater throughput.

- Embroidery Area: Generous field sizes (e.g., 400x450mm, 500x800mm per head) accommodate large and complex designs. Larger fields reduce the need for re-hooping, saving time.

- Control System: Features advanced computerized control panels with user-friendly interfaces (e.g., 10-inch HD LCD touch screen). These systems offer intuitive design management, real-time status monitoring, and easy parameter adjustments.

- Memory Capacity: Substantial onboard memory (e.g., 100 million stitches, 1000 designs) allows for storage of a vast library of patterns, minimizing downtime for data transfer.

- Thread Break Detection: Automatic sensors detect thread breaks or run-outs, pausing the machine and alerting the operator, preventing incomplete or flawed embroidery.

- Automatic Trimming: Integrated thread trimming mechanisms cut jump stitches and excess thread, reducing manual labor post-embroidery.

- Network Connectivity: Often includes USB and LAN ports for seamless design transfer and integration with factory networks, supporting efficient workflow management.

Comparative Analysis: Industrial vs. `cheap 15 needle embroidery machine`

While a `cheap 15 needle embroidery machine` might appear attractive due to lower upfront costs, industrial-grade machines like ours offer significantly superior long-term value, performance, and reliability.

| Feature | Good Quality Industrial Multi-Head | Typical `Cheap 15 Needle Embroidery Machine` |

|---|---|---|

| Construction Quality | Robust, heavy-duty steel frame, precision-machined components for continuous operation. | Lighter construction, less durable materials, prone to vibration and wear under heavy use. |

| Production Output | Multi-head (2-20 heads) for simultaneous, high-volume production; 850-1200 SPM. | Single-head, lower SPM (e.g., 600-800 SPM), significantly less output. |

| Durability & Lifespan | 10-15+ years with proper maintenance, designed for 24/7 industrial environments. | Shorter lifespan (e.g., 3-5 years), often not suited for continuous heavy production. |

| Stitch Quality & Precision | Superior consistency, minimal registration errors, excellent detail even at high speeds. | Variable quality, potential for inconsistent tension, less precise detail. |

| Maintenance & Support | Comprehensive manufacturer support, readily available parts, structured maintenance schedules. | Limited support, difficulty in sourcing specific parts, higher downtime. |

| Software & Connectivity | Advanced control systems, robust memory, network integration for efficient workflow. | Basic control panels, limited memory, often only USB connectivity. |

Application Scenarios & Experience-Driven Case Studies

The true value of our industrial embroidery machines is best demonstrated through their practical application and the success stories of our clients. As prominent embroidery machine manufacturers, we provide solutions that empower businesses to scale their operations and diversify their product offerings.

Large-Scale Apparel Production:

A major garment manufacturer in Vietnam, specializing in uniforms for international brands, faced increasing demand for embroidered logos and emblems. Previously relying on smaller, less efficient machines, they struggled with bottlenecks. After implementing five of our 10-head, 15-needle machines, their daily output of embroidered patches and direct garment embellishments increased by over 300%. The multi-head efficiency allowed them to process multiple items simultaneously, significantly reducing lead times and improving order fulfillment rates. This investment positioned them as a more competitive supplier in the global market.

Custom Promotional Products:

A promotional products company in the UK needed to rapidly produce custom-embroidered caps and jackets for corporate events. Their existing machines couldn't handle the volume or the frequent design changes required for diverse client orders. Our Good quality factory use Multi heads 15 needles embroidery machines industrial computerized offered the flexibility and speed they needed. With 15 needles, quick color changes were effortless, and the robust build ensured consistent quality even with continuous operation. The company reported a 40% reduction in production time per batch and a noticeable improvement in overall product consistency, leading to higher client satisfaction and repeat business.

Textile Art and Home Decor:

An artisan studio specializing in custom home textiles and fine art embroidery sought a machine that could handle intricate, large-scale designs with exceptional precision. While their volume was lower than a factory, the complexity demanded industrial capability. Our machine’s advanced stitch control and stable operation provided the fine detail required for their high-value, bespoke pieces. The wide embroidery field allowed them to complete large tapestry-style designs without segmenting, preserving the artistic integrity of their work. This enhanced their reputation for quality and enabled them to undertake more ambitious projects.

Manufacturer Comparison & Competitive Edge (Authoritativeness)

In a competitive market, discerning buyers look for reliability, performance, and long-term value. As leading embroidery machine manufacturers, we distinguish ourselves through our unwavering commitment to quality and innovation.

What Sets Us Apart:

- Proven Expertise: With years of dedicated experience in industrial textile machinery, our engineering team possesses deep domain knowledge, translating into superior machine design and functionality.

- Rigorous Certifications: Our manufacturing processes adhere to international standards such as ISO 9001 for quality management. Our machines often carry CE certifications, signifying compliance with European safety, health, and environmental protection requirements.

- Strategic Partnerships: We collaborate with top-tier component suppliers (e.g., Japanese servo motors, German bearings, Italian electronic components) to integrate the best global technologies into our systems, ensuring maximum performance and longevity.

- Comprehensive Testing & Data Analysis: Before dispatch, every machine undergoes extensive testing, including continuous run-time tests for hundreds of hours to simulate real-world production. Performance data, such as stitch accuracy deviation, vibration analysis, and power consumption, is meticulously recorded and analyzed to ensure optimal output and efficiency.

- Innovation-Driven Development: We continuously invest in R&D to incorporate the latest advancements, such as enhanced digital control systems, advanced material handling, and energy-efficient designs.

Why Choose Our Good quality factory use Multi heads 15 needles embroidery machines industrial computerized:

Compared to other industrial machines, our product stands out for its balanced combination of high-speed capability, precise embroidery, and user-friendly operation. It offers exceptional return on investment through reduced labor costs, increased throughput, and minimal maintenance requirements. Our authoritative standing in the industry is built on a track record of delivering reliable, high-performance machinery.

Customization Solutions & After-Sales Support (Trustworthiness)

Recognizing that every industrial operation has unique requirements, we, as experienced embroidery machine manufacturers, offer flexible customization and robust after-sales support to ensure maximum customer satisfaction and machine uptime.

Tailored Customization Options:

While our Good quality factory use Multi heads 15 needles embroidery machines industrial computerized comes with a powerful standard configuration, we can adapt certain aspects to specific production needs. This includes variations in the number of heads, customized embroidery field sizes, integration with specialized hooping systems (e.g., cap frames, sequin devices, cording attachments), and tailored software solutions for workflow management. Our technical team works closely with clients to understand their unique challenges and propose the most effective machine configuration.

Comprehensive Customer Support & Training:

- Installation & Commissioning: Our skilled technicians provide on-site installation and commissioning services to ensure your machine is set up correctly and integrated seamlessly into your production environment.

- Operator Training: We offer comprehensive training programs for your technical staff and operators, covering machine operation, basic maintenance, troubleshooting, and software usage. This empowers your team to maximize machine efficiency and minimize operational errors.

- Technical Assistance: Our dedicated support team is available via phone, email, and remote diagnostics to address any technical queries or issues promptly.

- Spare Parts Availability: We maintain a substantial inventory of genuine spare parts, ensuring quick availability and minimizing downtime for repairs.

Long-Term Value vs. `cheap industrial embroidery machines for sale`

When considering `cheap industrial embroidery machines for sale`, it's crucial to evaluate the total cost of ownership rather than just the initial price. Lower-priced alternatives often come with hidden costs such as frequent breakdowns, expensive spare parts, lack of reliable support, and inferior stitch quality leading to higher rejection rates. Our machines, while a significant investment, offer superior long-term reliability, lower operational costs, and consistent high-quality output, translating into a much stronger return on investment. The advanced features and robust build quality mean fewer interruptions and a longer productive life for your equipment.

Frequently Asked Questions (FAQ)

Q1: What is the typical lead time for an order of your multi-head embroidery machines?

A1: The standard delivery cycle for our Good quality factory use Multi heads 15 needles embroidery machines industrial computerized typically ranges from 4 to 8 weeks, depending on the number of heads, specific customizations, and current production schedule. We provide an estimated delivery date upon order confirmation and keep you updated throughout the manufacturing and shipping process. Expedited options may be available for urgent requirements.

Q2: What kind of warranty do you offer on your industrial embroidery machines?

A2: We stand behind the quality of our products. Our industrial embroidery machines come with a standard 12-month warranty covering major mechanical and electrical components from the date of installation or shipment, whichever comes first. Extended warranty options and comprehensive service contracts are also available for enhanced peace of mind. Specific warranty terms will be detailed in your purchase agreement.

Q3: How often does the machine require maintenance, and what does it involve?

A3: Our machines are designed for minimal maintenance, but regular care is crucial for longevity. We recommend daily cleaning (dust, lint removal), weekly lubrication of key moving parts, and monthly checks of thread tension and needle condition. A more comprehensive quarterly or semi-annual preventative maintenance check by a qualified technician is advisable to ensure optimal performance and address any potential wear and tear. Our detailed maintenance manual provides a full schedule and instructions.

Q4: Are your machines compatible with standard embroidery digitizing software?

A4: Yes, our industrial embroidery machines are designed to be highly compatible with standard embroidery file formats, most commonly DST and DSB. This ensures seamless integration with virtually all professional digitizing software on the market, allowing you to use your preferred design tools without compatibility issues. Designs can typically be transferred via USB or directly over a network connection.

Conclusion

As leading embroidery machine manufacturers, our commitment extends beyond delivering machinery; we provide comprehensive solutions that drive efficiency, enhance quality, and foster long-term growth for industrial enterprises. The Good quality factory use Multi heads 15 needles embroidery machines industrial computerized exemplifies our dedication to engineering excellence, offering unparalleled performance, durability, and versatility. By choosing our advanced embroidery solutions, businesses can confidently meet the demands of a dynamic textile market, ensuring precision, productivity, and profitability. We invite you to experience the difference that superior engineering and dedicated support can make to your operations.

References:

- Textile Industry Strategic Analysis: Global Market Trends and Technology Adoption.

- Advances in Industrial Automation: Precision Manufacturing Techniques for Textile Machinery.

- International Organization for Standardization (ISO) 9001:2015 Guidelines for Quality Management Systems.

- The Impact of Multi-Head Embroidery Technology on Apparel Production Efficiency.

- Sustainable Manufacturing Practices in the Textile Sector: Energy Efficiency and Waste Reduction.

-

Embroidery Machine Manufacturers: Best Buy & Industrial Models

NewsAug.11,2025

-

High Efficiency Multi Head Embroidery Machines | Flat & T-Shirt

NewsAug.10,2025

-

Computerized T-Shirt Embroidery Machines: Flat & Affordable

NewsAug.09,2025

-

Cheap Computer Embroidery Machine Price: Pro & Cap Models

NewsAug.08,2025

-

Professional Embroidery Machine: Precision & Performance

NewsAug.07,2025

-

T Shirt Embroidery Machine | Multi-Head, 12 & 15 Needle

NewsAug.06,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy