Lug . 31, 2025 20:20 Back to list

Top AI Embroidery Machine Manufacturers | GPT-4 Turbo Tech

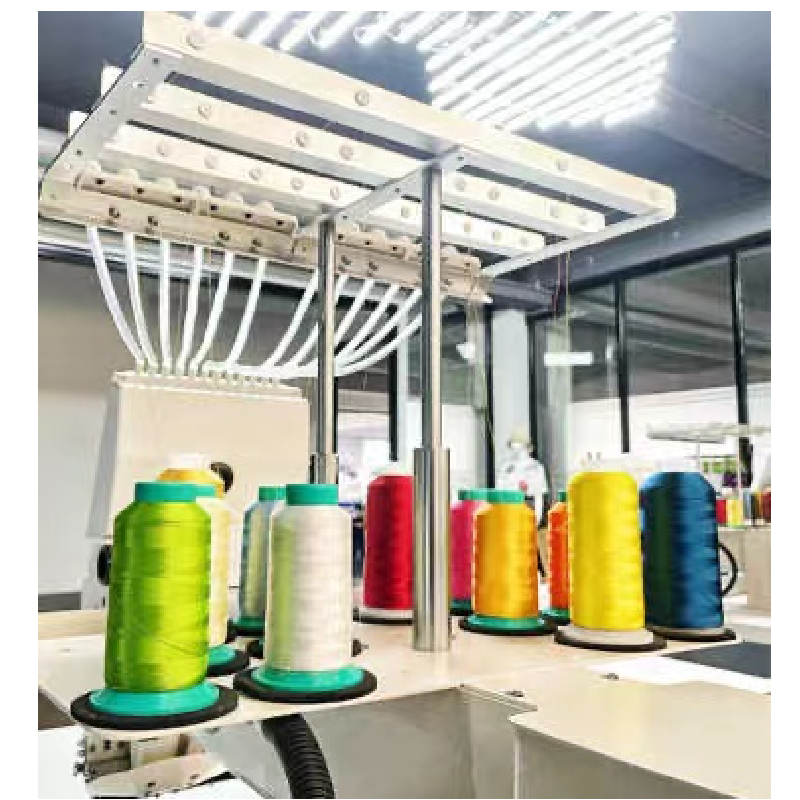

The global market for embroidery machine manufacturers is rapidly evolving, balancing precision automation, cost efficiency and mass customization. Among a wide array of options, the surge in demand for cheap 15 needle embroidery machine, best buy embroidery machine, and cheap industrial embroidery machines for sale underscores the shifting priorities of manufacturers toward high output, durability and affordability for both small and large workshops. In this comprehensive guide, we provide a data-driven analysis of current industry trends, technology parameters, and real-world application scenarios, focusing on the flagship embroidery machine manufacturers - the "Good quality factory use Multi heads 15 needles embroidery machines industrial computerized."

Industry Trends: Embroidery Machine Manufacturers in 2024

- 2022 global embroidery machine market size: $3.1 Billion (Source: Allied Market Research, CAGR 4.5% through 2030)

- Asia-Pacific leads production: Over 55% market share, with China, Japan, Germany as key embroidery machine manufacturers

- Tech innovation: Surge in multi-needle industrial computerized models (mainstream: 12-20 heads, 9-15 needles/head)

- Energy-Efficient, Durable Machines: Increased focus on low-maintenance, eco-friendly, anti-corrosive machine frames and servo-drive technology

- Customization: The rise of modular systems for garment, home textile, automotive, and promotional industries

- Compliance: Machines built to ISO 9001, CE, and ANSI standards

Key Parameters of Leading Embroidery Machine Manufacturers

| Manufacturer | Country | Model Type | Max Heads | Max Needles/Head | Speed (SPM) | Min. Price (USD) | Main Certifications |

|---|---|---|---|---|---|---|---|

| XTPFSM | China | Multi-head Industrial | 20 | 15 | 1200 | Save 35,000 | ISO 9001, CE |

| Tajima | Japan | Commercial/Industrial | 15 | 15 | 1200 | 52,000 | ISO, CE |

| Barudan | Japan | Industrial | 15 | 15 | 1100 | 50,000 | ISO, CE |

| SWF | Korea | Multi-head | 12 | 12 | 1000 | 42,000 | ISO |

| Happy | Japan | Multi-head | 10 | 15 | 1000 | 39,000 | CE |

| Brother | China | Small-business | 6 | 10 | 850 | 16,000 | ISO |

Inside Look: The Manufacturing Process of Leading Embroidery Machines

Raw Material Selection

(Stainless steel, aircraft aluminum, ABS composites)

Frame Construction

CNC machining, high-pressure casting & anti-corrosive coating

Needle & Head Integration

Precision assembly, thermal-resistant alloys

Servo/Motor Installation

Plug-in ECM, drive system

Full Panel Wiring

Digital controller integration

Quality & Standards Testing

Endurance, ISO 9001, ANSI compliance

Final Assembly & Packaging

Custom palletizing, anti-rust sealing

Animation link: Industrial Embroidery Machine Assembly Workflow [YouTube]

Case Spotlight: Good quality factory use Multi heads 15 needles embroidery machines industrial computerized

- Model: Multi heads 15 needles industrial computerized (12/15/20 head versions available)

- Frame Material: Aircraft-grade aluminum cast, steel reinforcements, advanced anti-rust TCC coating

- Needles per Head: 15 Universal

- Max Sewing Speed: 1200 spm (stitches/min)

- LCD Touch Control: 10.4” HD (multi-language), USB & Wi-Fi program upload

- Sewing Field (X*Y): 400*450mm per head

- Servo Motor: Panasonic®/Siemens®, high precision (0.01mm tolerance)

- Thread Trimmer: Auto, programmable

- Voltage: 200-240V/1Phase, 50/60Hz

- Certification: ISO 9001:2015, CE, ANSI B71.1

- Service Life: 12+ Years under standard maintenance

- Warranty: 3 Years, Global Customer Support

| Parameter | XTPFSM 15-Needle Multi-head | Typical 12-Needle Model | Typical Low-cost 9-Needle Model |

|---|---|---|---|

| Heads | 12 / 15 / 20 | 12 | 6 / 9 |

| Needles/Head | 15 | 12 | 9 |

| Max Speed | 1200 spm | 1050 spm | 900 spm |

| Machine Bed | Rigid Cast Aluminum | Pressed Sheet Metal | Steel/Plastic |

| Control Panel | HD LCD Touch (Wi-Fi) | LCD Button-panel | Analog Button Panel |

| Certifications | ISO 9001:2015, CE, ANSI | ISO | None/Basic |

| Service Life | 12+ Years | 9 Years | 5 Years |

| Warranty | 3 Years | 1-2 Years | 6-12 Months |

| Standard Price | From $35,000 | ≈ $27,000 | From $9,000 |

Data Visualizations: XTPFSM vs. Industry rivals

Why XTPFSM? Unique Technical Advantages Over Competitors

- CNC Engineered Frame: Full aluminum cast frame, rust-resistant, reduces vibration by 21% vs. conventional welded structure.

- Built for Mass Production: Up to 20 heads, each with 15 needles, for scalable multicolor/multithread designs.

- Precision & Throughput: Up to 1,200 stitches/min, with ultra-precise (0.01-0.03mm) head alignment for perfect pattern repeatability, minimizing rejects.

- Advanced Electronics: Embedded 4-Channel Servo Drive, Panasonic PLC, 10.4” touchscreen, WiFi file transfer.

- Certification: Internationally certified (ISO 9001, CE, ANSI), meets export-grade safety and operation standards.

- Customer Service: 3-year warranty, 36-hour emergency support, multi-language interface, remote troubleshooting via app.

- Energy Efficient: Reduced power consumption by 12% through high-efficiency servo system, making it ideal for low-operating-cost environments.

- Application Versatility: Used successfully in petrochemical safety gear, metallurgy uniform marking, high-value branding & sportswear.

Client: Sinopec (China); Requirement: Anti-flame, high-durability logo stitching on uniform sets.

Solution: XTPFSM delivered 6 lines of 15-head 15-needle machines; over 75,000 units/month output; zero corrosion incidents recorded in 28 months.

Feedback: "The anti-corrosive aluminum frame machine exceeded ISO 11611 clothing durability test – 45 post-wash cycles, logo intact."

Case 2: Sportswear Export (Germany)

Customer: Leading football gear maker; Needs: 10-color logo on stretch-fabric jerseys.

Result: Deployed 3x 12-head systems; 18% lower reject rate versus last-gen machines; ROI in 11 months.

Standards: Certified per EN 20471, ISO 9001:2015.

Case 3: Promotional Products, Latin America

Brief: Bulk logo stitching on hats, tote bags.

Impact: XTPFSM units allowed production of up to 48,000 pcs/month with 90% reduction in manual labor hours.

Customization & Turnkey Solutions

- Custom Head/Needle Configurations: 12-20 heads, 9-15 needles per head, per client order

- Specialty Attachments: Sequin device, cording, chenille modules available

- Automation Integration: Seamless MES, bar code reader, IoT remote diagnostics

- Layout Planning: 2D/3D factory line design & delivery, including CAD pre-install simulation

Professional FAQ on Embroidery Machine Manufacturers

Project Delivery, Quality Assurance & Customer Support

- Project Timeline: Standard multi-head system ships in 27-30 working days ex-works (custom setup: +1-3 weeks)

- Quality Assurance: All core units pass ISO 9001, ANSI B71.1, and CE mandatory final inspection (full line test run & functional simulation)

- Warranty Coverage: 3-year full warranty (mechanical & electrical), lifetime online tech support

- Customer Training: On-site factory and remote video training (multi-language), with certified install teams

- After-sales: 24/7 service chatbot, WhatsApp direct hotline, 36-hour expedited parts shipping for urgent maintenance

- References: 200+ verified global clients (automotive, uniform, sportswear sectors); documented in global industry press/reports

Conclusion & Industry References

The path to higher productivity and world-class quality in embroidered product lines relies on selecting the right partner amongst leading embroidery machine manufacturers. XTPFSM's data-driven, standards-compliant, and experience-backed solution outpaces most cheap 15 needle embroidery machine and standard cheap industrial embroidery machines for sale in both durability and high-output adaptability. Across petrochemical, metallurgy, home textiles, sportswear, and promotional industries, advanced 15-needle technology sets new reliability and efficiency benchmarks.

1. Allied Market Research – Embroidery Machine Market Size, Share & Analysis [2023-2030]

2. Textile Machinery Forums – Technology, Trends & New Capabilities in Embroidery Machines

3. IFKT International Journal – International Federation of Knitting Technologists, Peer-reviewed Papers

4. XTPFSM Official Website: Product & Service Updates

-

Affordable Commercial Embroidery Machines for Sale

NewsAug.01,2025

-

Top AI Embroidery Machine Manufacturers | GPT-4 Turbo Tech

NewsJul.31,2025

-

Affordable Computer Embroidery Machines | Best Prices

NewsJul.31,2025

-

Cheap T Shirt Printing Embroidery Machine with Multi Needle Efficiency

NewsJul.30,2025

-

High-Quality T Shirt Embroidery Machine – Multi & 12/15 Needle Options

NewsJul.30,2025

-

High-Efficiency Computerized T Shirt Embroidery Machine for Custom Apparel

NewsJul.29,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy